The Duravant family of operating companies serve the food processing, packaging and material handling segments.

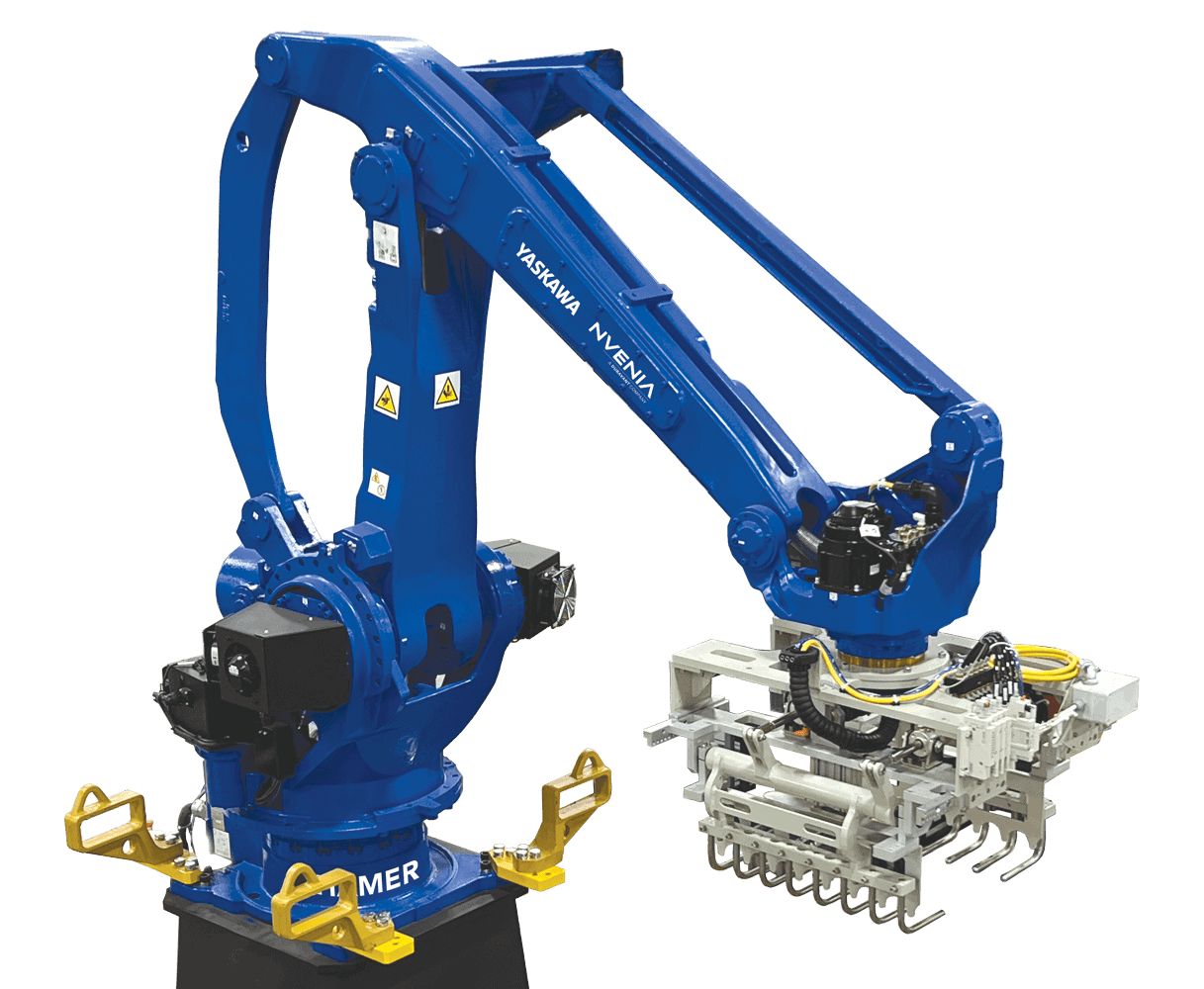

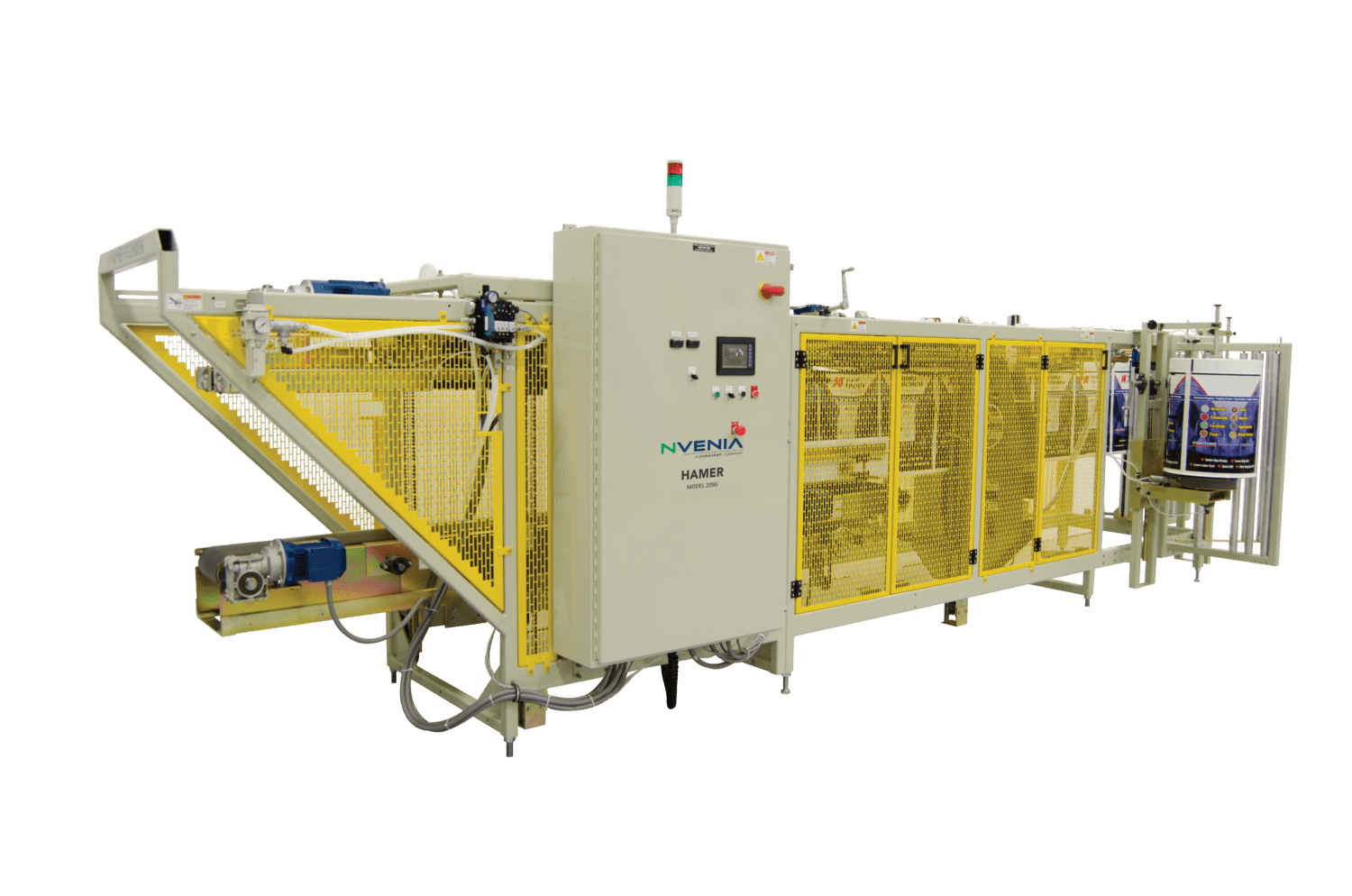

Hamer Brand Semi-Automatic Robotic Bag Palletizer

Our Hamer Brand Semi-Automatic Robotic Palletizer maximizes production while providing unsurpassed ease of use, providing 80% of palletizing automation at a lower cost than fully automatic systems.

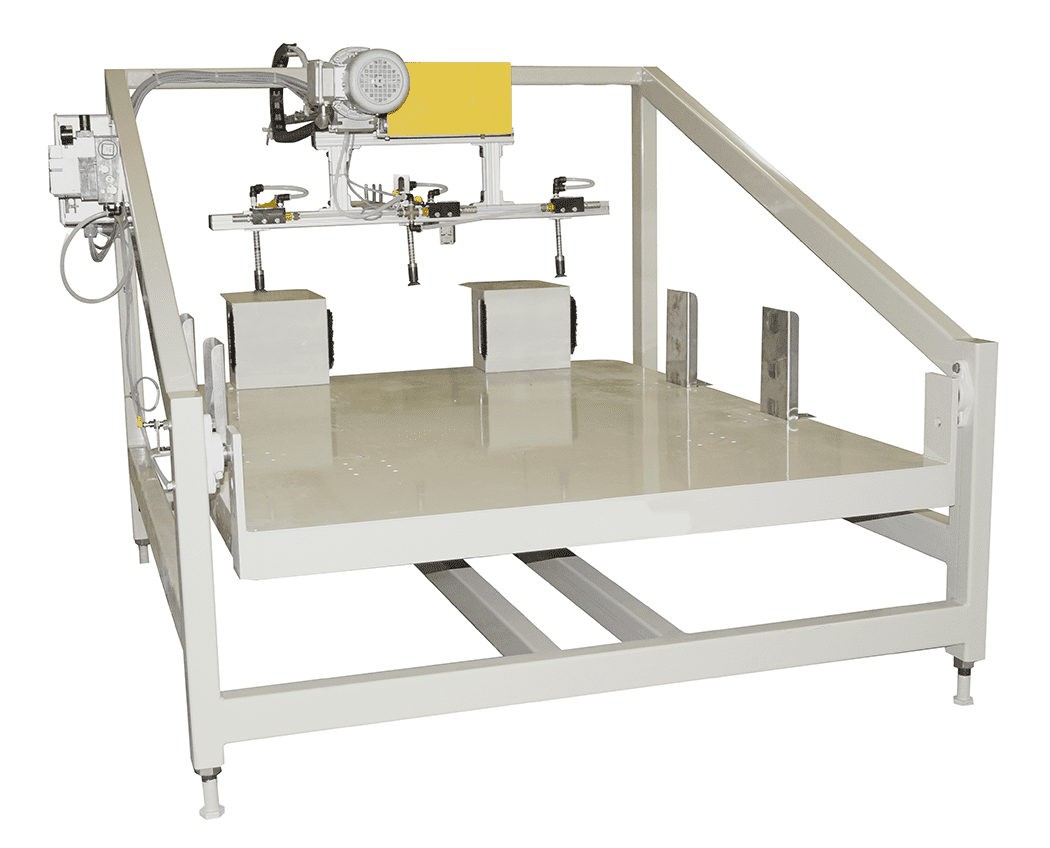

A semi-automatic configuration describes an operation where bags are fed to the palletizing robot and placed on a stacking station with floor positioned empty pallets. Full pallets are then picked up by fork trucks or pallet jacks for wrapping prior to shipment. Both single and dual-stack robotic palletizing systems are available. In the dual-stack system, the robot continues to stack product on an empty pallet while the first pallet is removed, allowing for uninterrupted palletizing and increased operational efficiency.

This system also can include a stack box for Soil, Mulch and Compost applications. This revolutionary design provides a robust solution for demanding plant environments. With a heavier side wall, improved hinging, and added pneumatics, it is designed to keep the stack box functioning for years and years to come.

Are you interested in this product?

We are here to help.

Features

Standard

A wide variety of configurations and system designs are available, including a Palletizer Preventative Maintenance service program.

An RPM Palletizer System typically includes:

- PL 190/100 4 axis, 100KG robotic arm (or MPL160 II or MPL 100)

- YRC1000 Robot Controller (or DX200)

- 10 meter master control cable

- High-Speed main axis servo

- 1 or 3 pallet stack

- Robot mounting base plate/riser

- 18” robot riser

- EasyPic operator software pallet configuration

- MaxPic pallet configuration

- Industrial End of Arm Tool options

- ANSI/RIA safety protocols

Options

For a full range of options, please contact your regional sales manager.

- Various safety cell guarding options

- Floor mounted wire tray

- Additional E-stops

- Additional pallet patterns

- End Of Arm Tooling:

- Bag Clamp, single or multiple pick

- Bag Clamp, fixed size, manually adjustable or, servo/automatically adjustable

- Case Grip, single or multiple pick

- Fork Style, multiple pick

- Vacuum, single or multiple pick

- Multi-function end of arm tooling:

- Pallet pick/place

- Slip-sheet pick/place

- Auto tool change

- Auto height sensor

- Multiple pick points

- Multiple stack points

- Custom conveying for bag, case, bucket/pails conditioning, in-feed, pacing, picking, power curves, checkweighing, metal detection, accumulating

- Corrosion resistant packages for conveyors

- Pallet racks

- Slip sheet racks

- Mulch/soil stack box

- Quad muting light curtains for continuous operation (semi automatic)

- Automated, semi-automated or manual bagging systems

Standard Specs

Standard Specs

Speed

Palletizing Rate: 22 Bags per minute

Electrical Power Requirements

460VAC, 3 Ph, 60 Hz

Compressed Air Requirements

2-10 CFM at 80 psi (design dependent)

Bag Weight

60 lbs maximum

Max Pallet Height

60″