The Duravant family of operating companies serve the food processing, packaging and material handling segments.

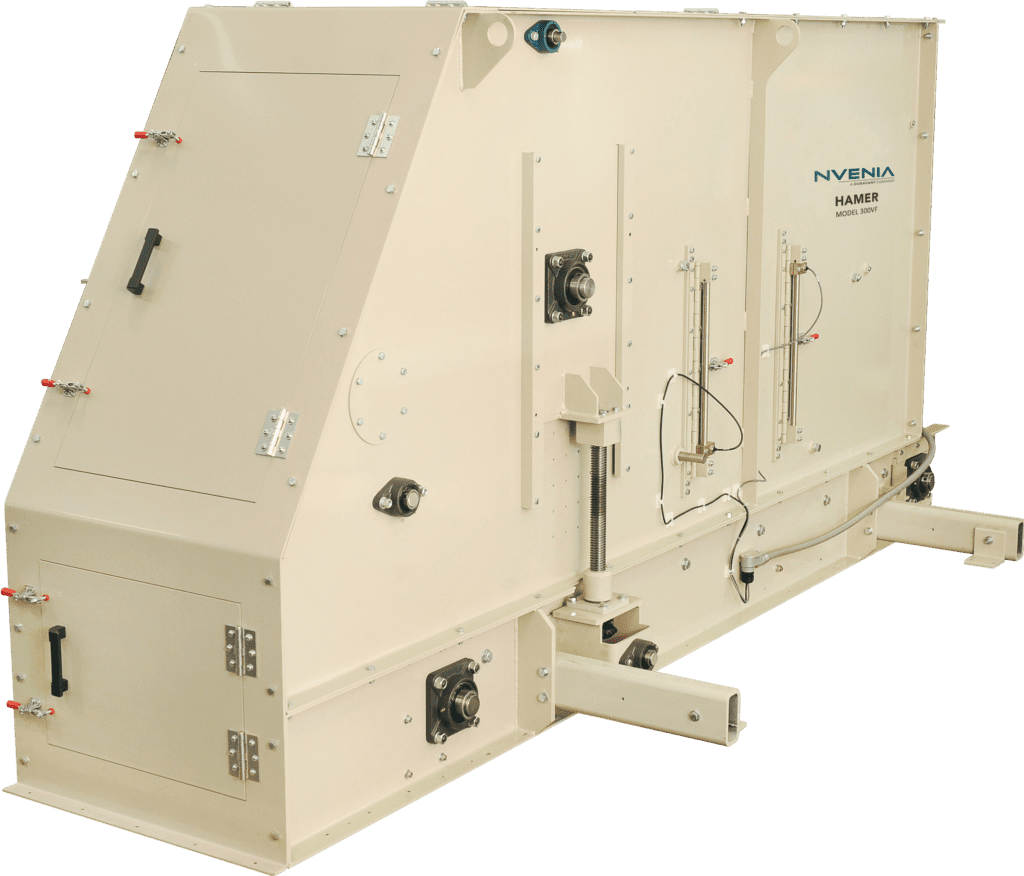

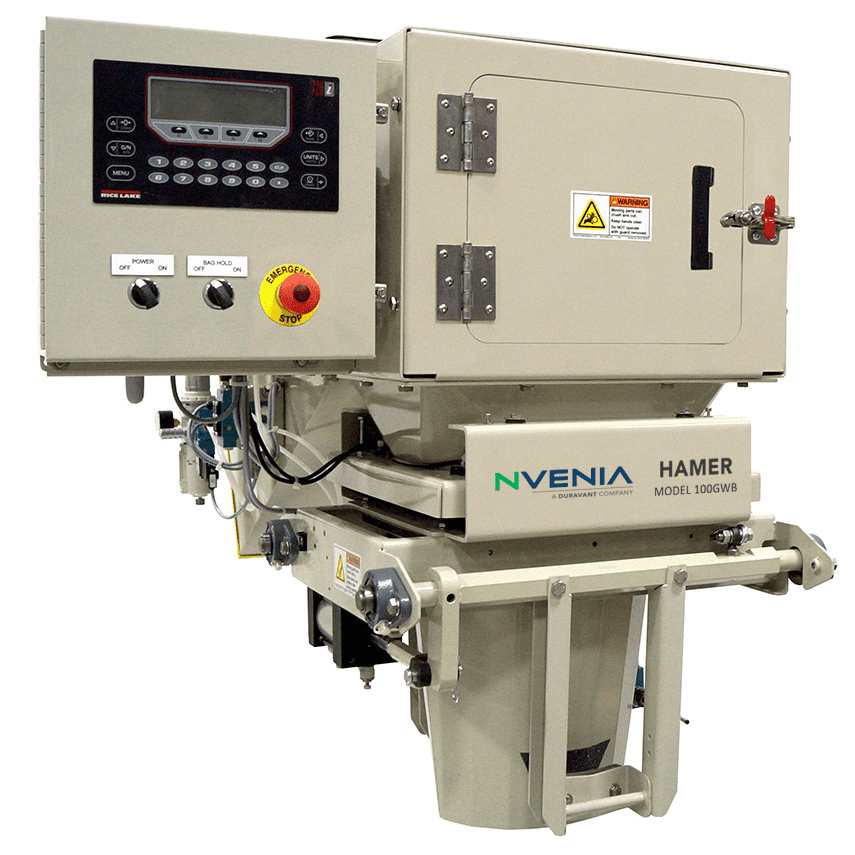

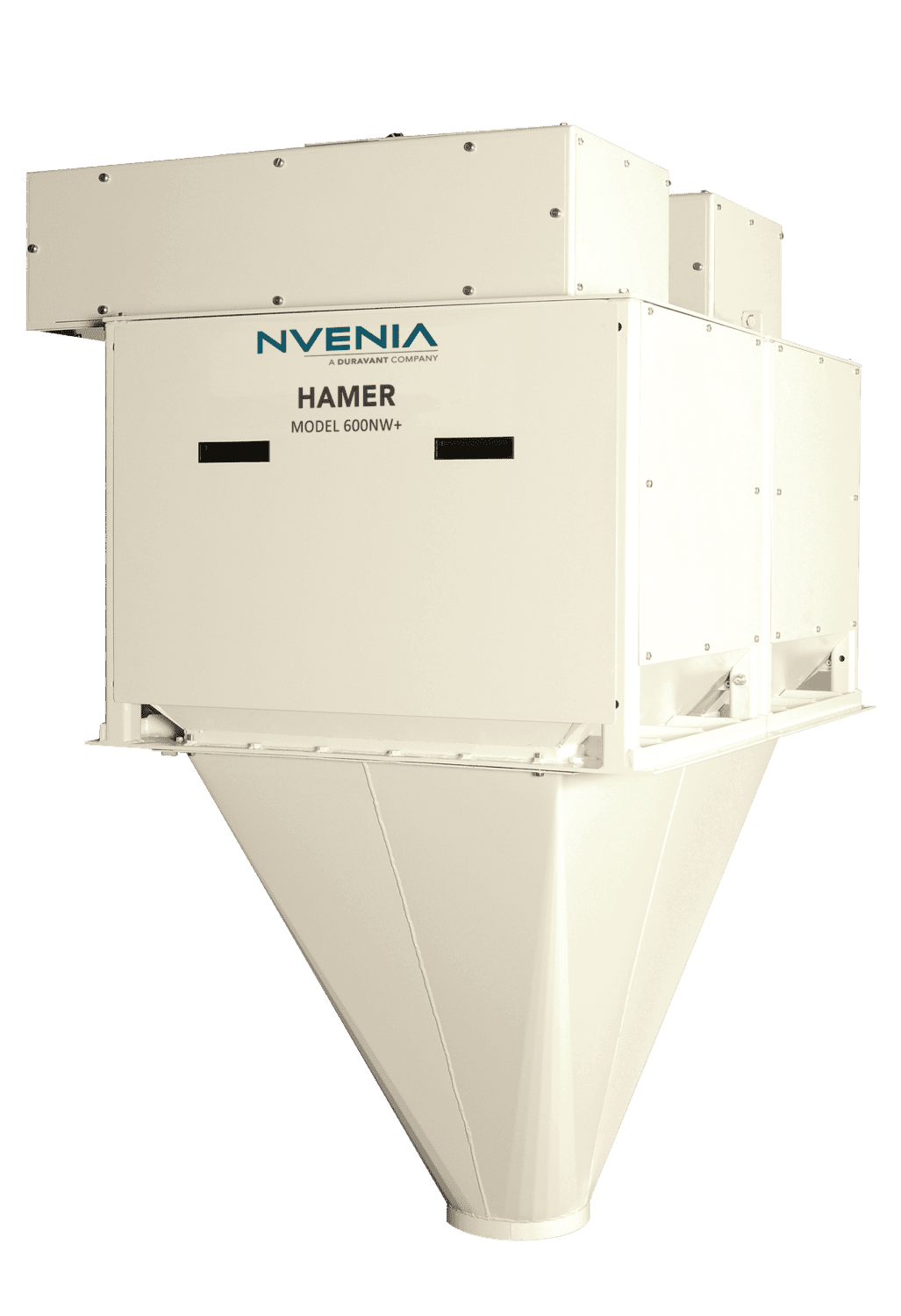

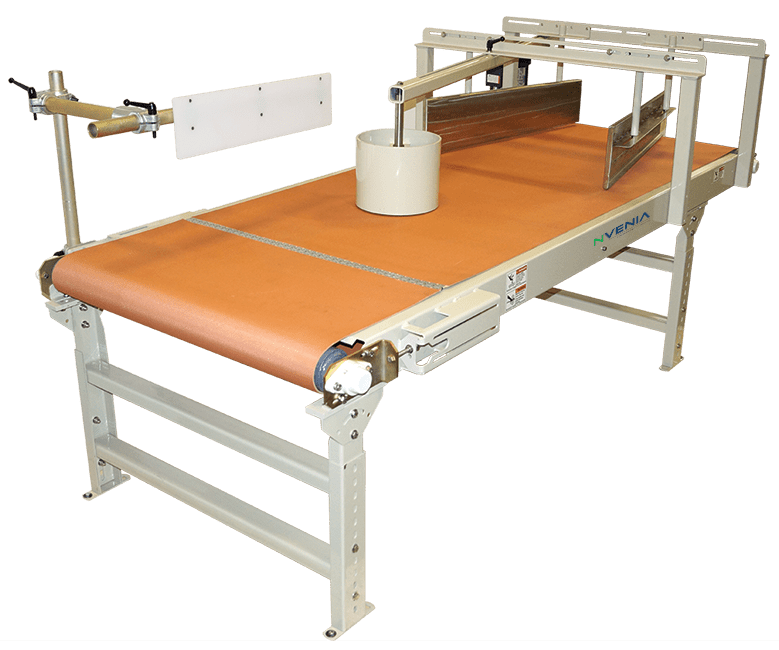

Hamer Brand Model 300VF Volumetric Filler

Our Hamer Model 300VF volumetric filler provides consistent product flow for hand bagging or to automated form, fill and seal packaging machines. Perfect for volumetric filling of soil, compost, mulch, aggregates, feed and any other products sold by volume. The Model 300VF employs a counter-rotating leveling wheel to provide fast, consistent product flow. Maintenance and downtime have been significantly reduced as there are no leveling chains or clutch brakes to fail. When combined with a Hamer Model Form, Fill, Seal Machine, the filler control can be integrated into a single operator console.

Are you interested in this product?

We are here to help.

Features

- Heavy duty steel construction

- Simple touch screen controls

- 4″ x 4″ x 1/4″ structural steel stand

- VFD drives on leveling wheel and feed belt

- 1/4″ steel leveling wheel

- Leveling wheel height adjustable from 2.5” to 8” for maximum dosing control

- Independently controlled product cut-off gate

- 4″ dust pickup port

- Single integrated control when combined with a Hamer model Form, Fill, Seal Machine

- 10 preset fill volumes

- Multiple access panels for easy clean out

- Quick release product discharge chute for fast changeout

- Easy access bearings and lubrication points

- NEMA 12 electronics enclosure

- Hand bagging chutes with automatic bag clamp

Standard Specs

Standard Specs

Machine Dimensions

144″ (366 cm) H x 66″ (103 cm) W x 103″ (262 cm) L

Product Discharge Height

- Manual: 48″ (122 cm)

- Automated: 57″ (145 cm)

Conveyor

20″ (51 cm) wide

Speed

Up to 35 BPM

Fill Range

8 quart to 3 cu. ft.

Electrical Requirements

460VAC, 3 PH, 60 Hz, 20 A

Air Requirements

5 cfm @ 80 PSI

Operating Temperature

Min. 40 degrees Fahrenheit (4.5 degrees Celsius)

Accessories

Accessories

Options:

- Soil or Rock gates

- Operator access platform

- Hardox ® product discharge chute – high abrasion resistance for rock applications

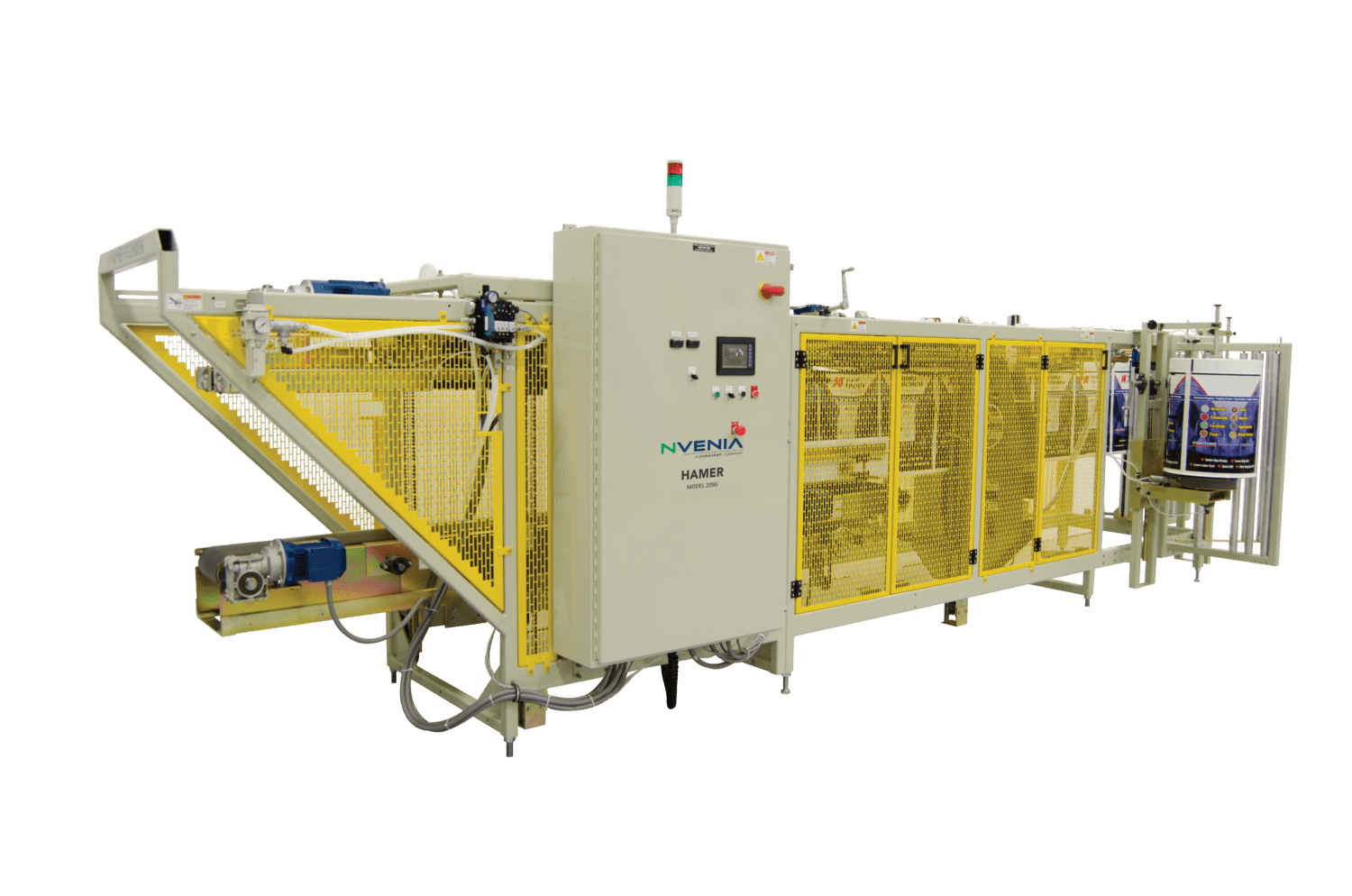

- Product infeed chute – 304 stainless steel chute for connecting to Hamer Model 2090 FFS equipment

- Product discharge chute – 304 stainless steel chute for connecting to Hamer Model 2080/2040 FFS equipment

- Reclaim hopper assembly

- Belt clean out scraper

- 5 hp or 10 hp variable speed drives

- Additional motor starters for bulk infeed control

- Manual bagging operator station

- FFS operator station – NEMA 12 control panel with touchscreen controls

- Manual bagging chute

- Hardox ® manual bagging chute