The Duravant family of operating companies serve the food processing, packaging and material handling segments.

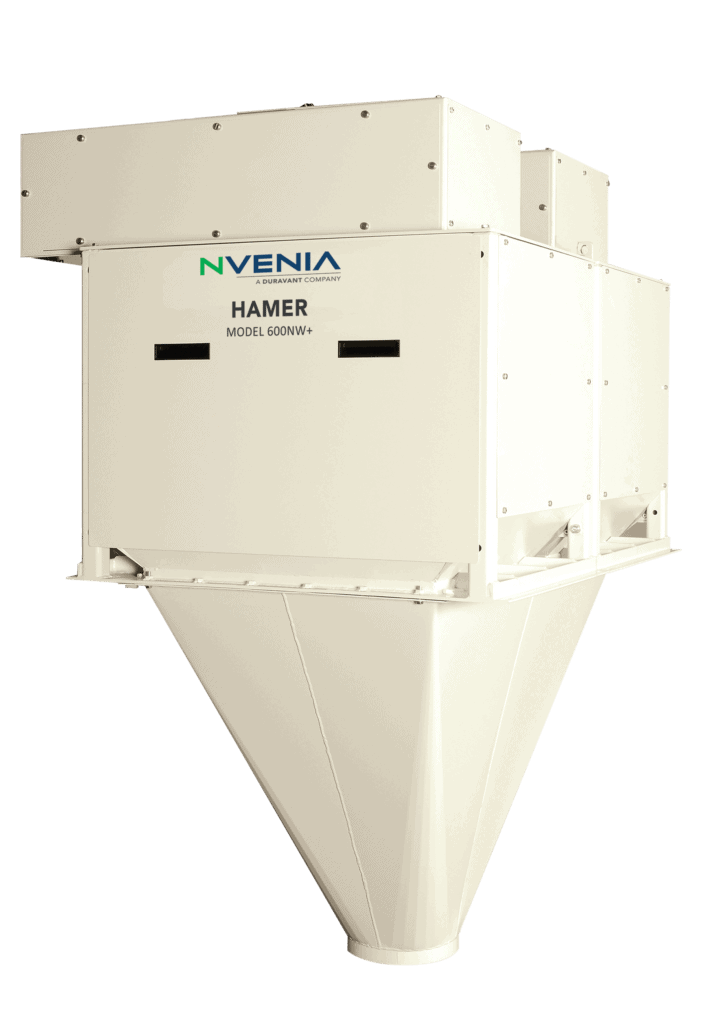

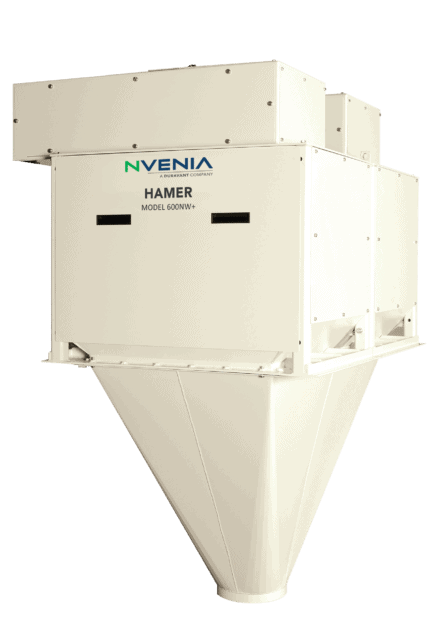

Hamer Brand Model 600NW+ Net Weigh Bagging Scale

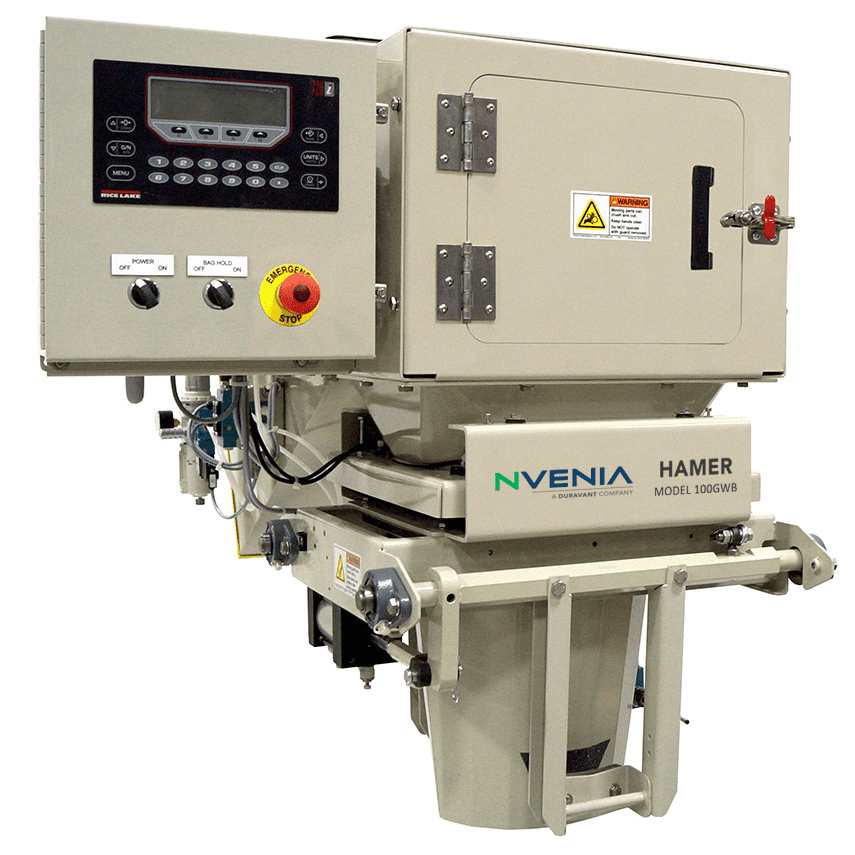

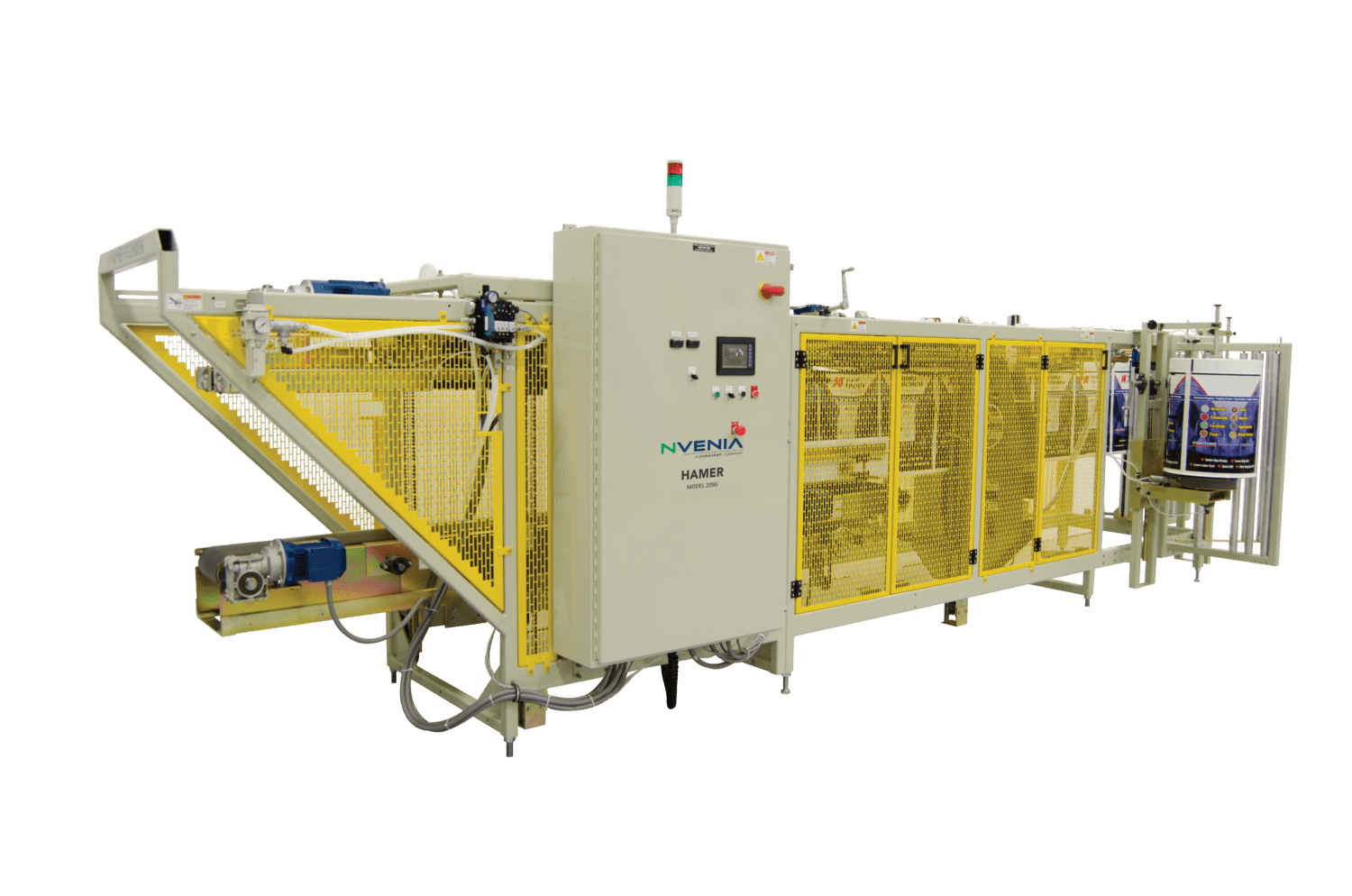

Our Hamer Model 600NW+ Net Weigh Bagging Scale sets the standard for durability, speed and accuracy in net weigh filling. Developed with industrial applications in mind, the Model 600NW+ has twice the steel of competitive models. It is available in a variety of formats to meet your unique application, including: Gravity, Gravity Servo, Belt feed, Vibratory, and Auger feed versions. In addition, a wide range of options are available to further configure the Model 600NW+ to your specific needs.

Are you interested in this product?

We are here to help.

Features

- Gravity, Gravity Servo, Belt, Vibratory, Gravity, Auger versions

- Heavy duty steel construction

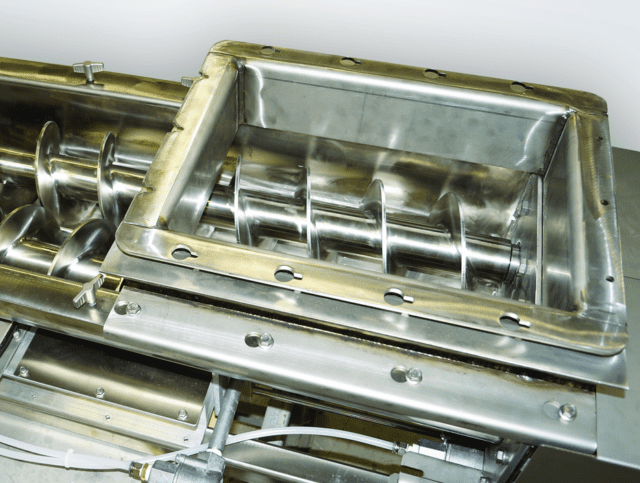

- 304 stainless steel contact surfaces or full stainless steel construction available

- Industrial grade pneumatics

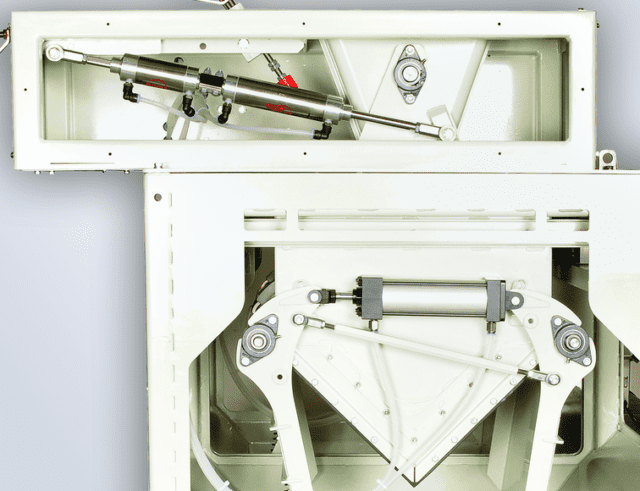

- Dual load cell design maximizes signal strength and stabilization for increased accuracy and weighment speed

- Rugged weigh hopper doors increase operational life

- 4” dust collection port (1 per scale, 2 total)

- Steep weigh hopper doors ensure fast product discharge, no residue

- Fully enclosed casing with easily detachable side panels for easy access

- Rice Lake 920i digital weigh indicator

- Large, easy to read weight display

- Controller stores up to 100 pre-set formulas

- Gravity Feed Model:

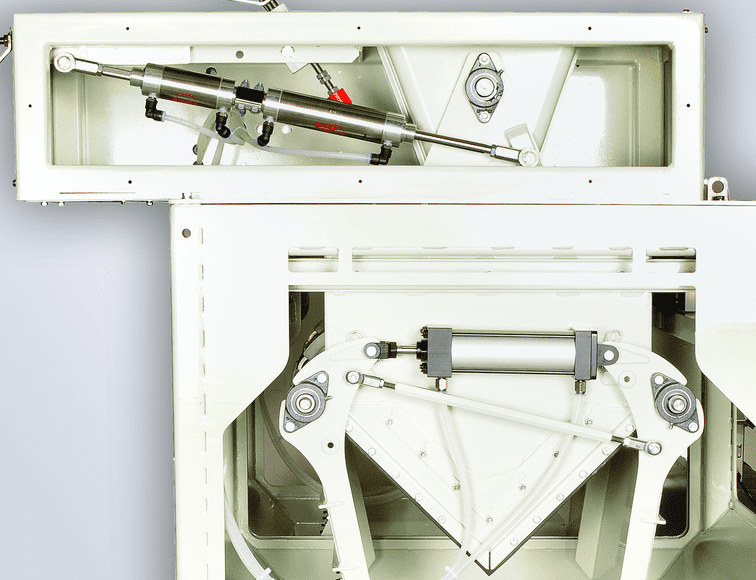

- Heavy Duty two position pneumatic control

- Easy adjust bulk / dribble for free flowing or granular products

- Servo Gravity model:

- Digitally controlled servo motor

- Precise control for bulk / dribble for free flowing or granular products

- Extremely high speed

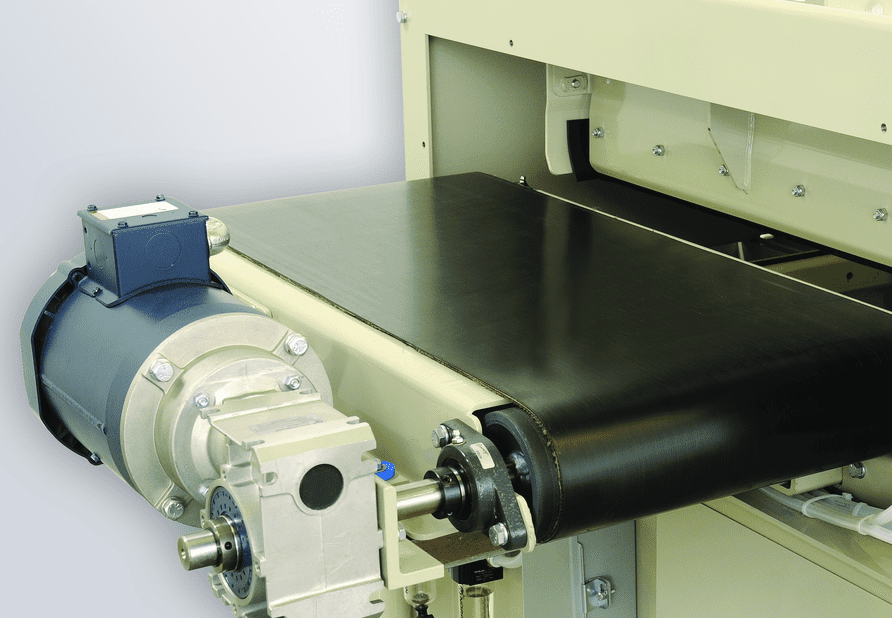

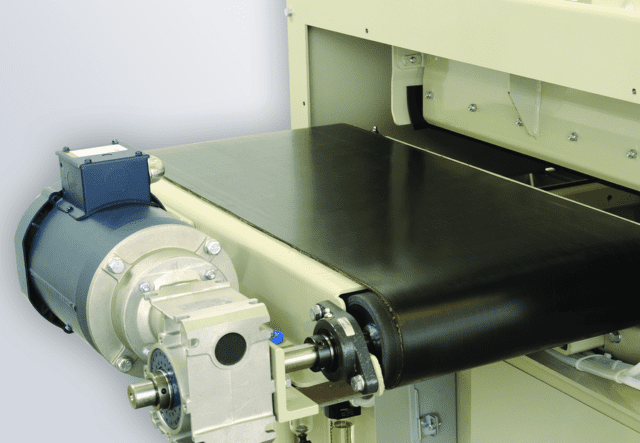

- Belt drive model:

- Two speed VFD motor for belt fast/slow fill

- Easy Clean™ slide out belt assembly

- Self tracking belt with lag drive and wing take up pulleys

- Adjustable product leveling

- Cut off gate to control product free fall

- Vibratory feed model:

- Two speed Eriez brand vibratory feeders

- Feeders are equipped with 304 Stainless steel ARS side and bottom liners for extended wear with abrasives

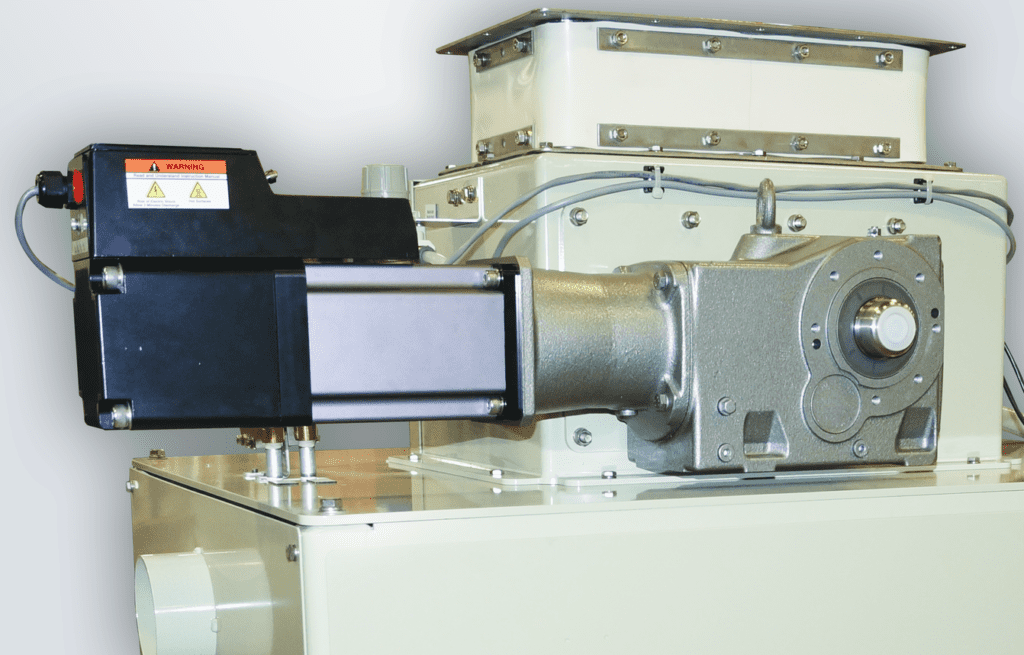

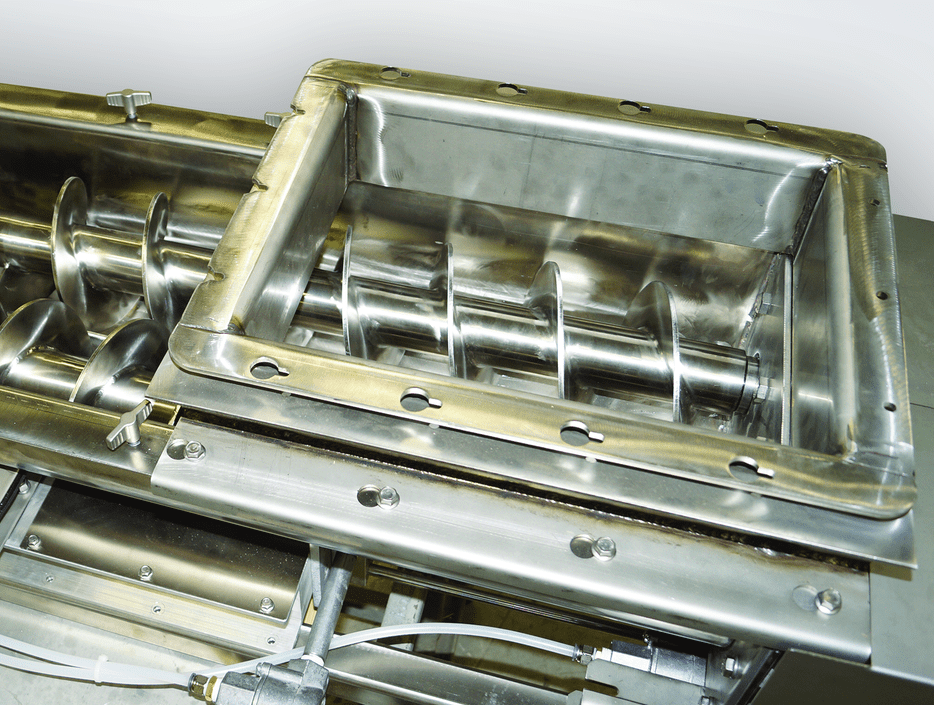

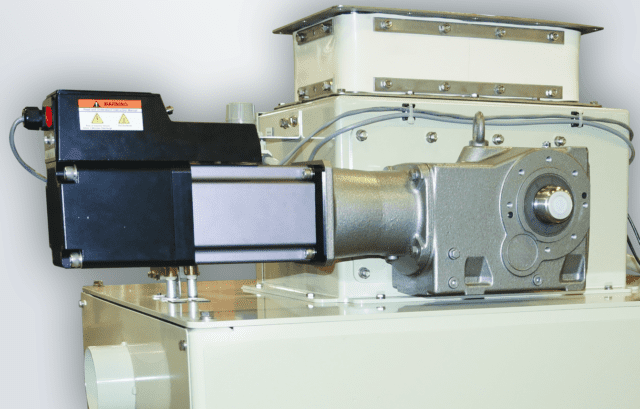

- Auger feed model:

- VFD 3 hp motor

- Mild steel and stainless steel augers available

- Easy removal slide gate for auger removal and cleaning

- Salina/Vortex slide gate cutoff

- NEMA 4X 304SS controller enclosure

- RS-232/485 communications output to printers and other devices

- Controller is UL, CUL, OIML and NTEP approved

Standard Specs

Standard Specs

Accuracy

- Gravity and Gravity Servo models: +/- .5 oz (15g) @ 2 sigma

- Vibratory model: +/- 3.5oz (100g) @ 2 Sigma

- Belt Feed model: +/- 1.4 oz. (40 g) @ 2 sigma

- Auger Feed model: +/- 3 to 4 oz. (85- 114g) accuracy @ 2 Sigma

Speed

- Gravity model: Up to 26 BPM – simplex

- Gravity Servo model: Up to 30 BPM – simplex

- Vibratory Feed model:

- Belt Feed model: Up to 20 BPM – simplex

- Auger Feed model: Up to 12 BPM – simplex

Weighment Range

- 10 lb (5 kg) to 110 lb (50 kg)

Electrical Requirements

Gravity and Gravity Servo models:

- 110 VAC, single phase, 60 hz, 5 amp

Belt Feed model:

- 110 VAC, single phase, 60 hz, 5 amp

- 230/460VAC, 3 phase, 60 hz, 20 amp

Vibratory Feed model:

- 110 VAC, 60Hz, Single Phase, 5amp

- 230 VAC, 60HZ, Three Phase, 20 amp

Auger Feed model:

- 110 VAC, single phase, 60 hz, 5 amp

- 230/460VAC, 3 phase, 60 hz, 20 amp

Air Requirements

10 CFM@ 80 PSI Clean/Dry Air

Accessories

Accessories

OPTIONS:

- Hand Bagging Spouts: Center Grip, Dust Tight, Clamshell in multiple materials

- 304 Stainless Steel Construction

- 304/316 Stainless Steel Product contact points

- Hermetically sealed load cells

- Collating chutes for hand or automated bagging in multiple sizes and materials

- UHMW chute liners

- Multi-dump control

- Foot pedal control

- Capacitance or laser level sensors

- Rotary paddle sensor

- Ethernet connectivity

- 50 Hz operation

- Multiple scale support structures

- Full bag conveyors, bag top closers

- Automated bagging systems