The Duravant family of operating companies serve the food processing, packaging and material handling segments.

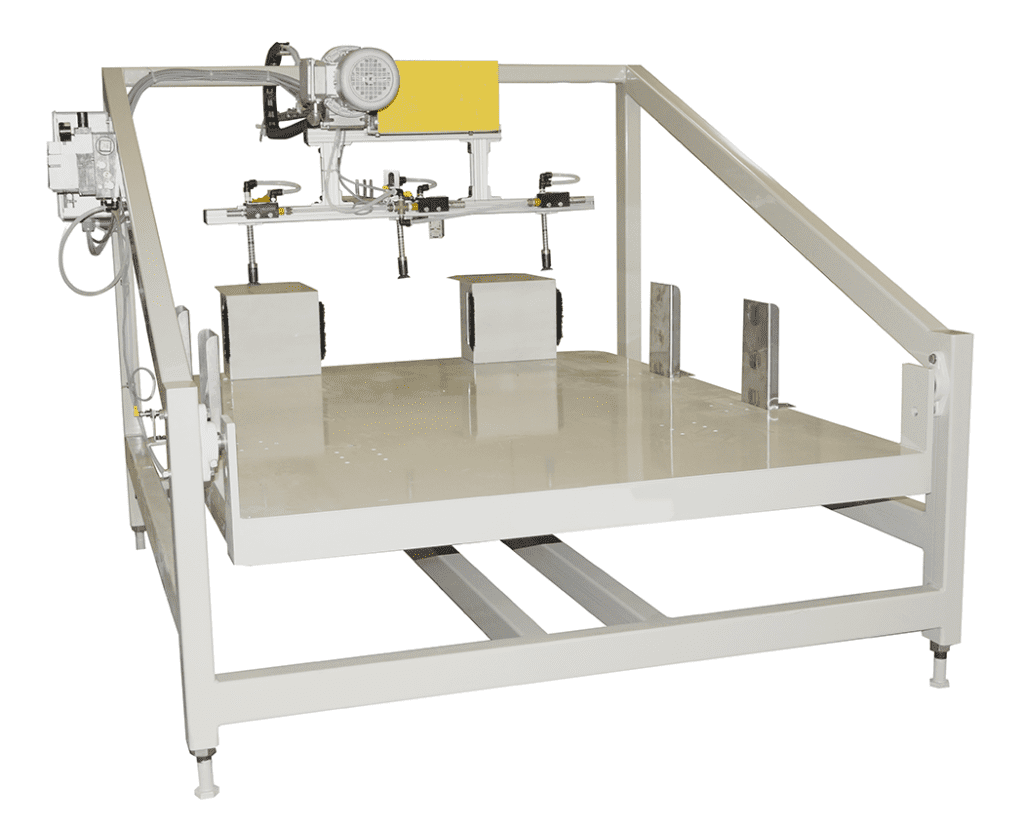

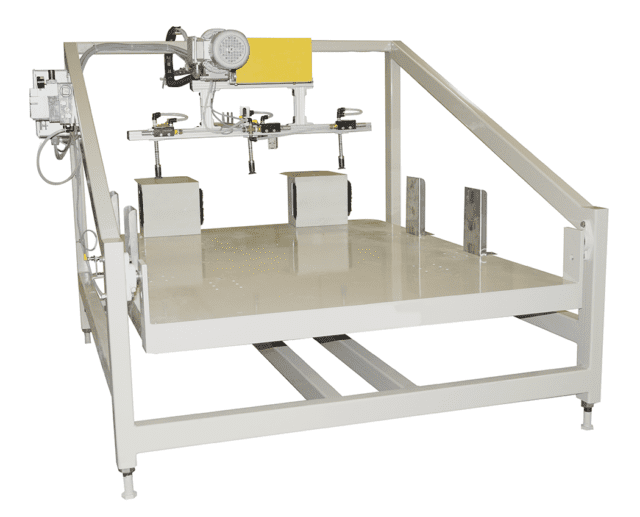

Hamer Brand Pallet Slip Sheet Dispenser

Our Hamer Brand Slip Sheet Dispenser picks up and delivers a slip sheet on top of an empty pallet for use in an automated palletizing system. It is built for endurance and reliability for use in challenging environments.

In operation, the dispenser will raise the stack magazine table after receiving a signal that a pallet is in place. When contact is made with the slip sheet stack, one sheet is picked with suction cups and a motor-driven carriage transports the sheet to the empty pallet. The carriage then returns to the home position to await the next pallet.

Are you interested in this product?

We are here to help.

Features

Standard

- Driven carriage motor

- Vacuum pick & place cups

- 1/4″ Structural tube steel frame

- Powder coat finish

- Bottom table pneumatic lift with flow control

- Photo-eye sensor to detect sheet presence

- Low level indicator

- 2 cycles/sheets per minute

- 1/3 hp TEFC motor

- Handles up to 48″x 48″ sheets and up to a 30″ stack

Standard Specs

Standard Specs

Power Requirements

230/460VAC, 3 Ph, 1.56A/0.78A

Compressed Air Requirements

15 CFM Maximum @ 80 PSI

Slip Sheet Specifications

- Material: Clean clay-coated paper, double-faced corrugated cardboard, cardboard or plastic

- Thickness: Minimum 32 mil (0.032 in), Maximum 250 mil (0.25 in)

- Maximum Size: 48″x48″

- Capacity: Approx. 10″ stack up to 250 lb.