The Duravant family of operating companies serve the food processing, packaging and material handling segments.

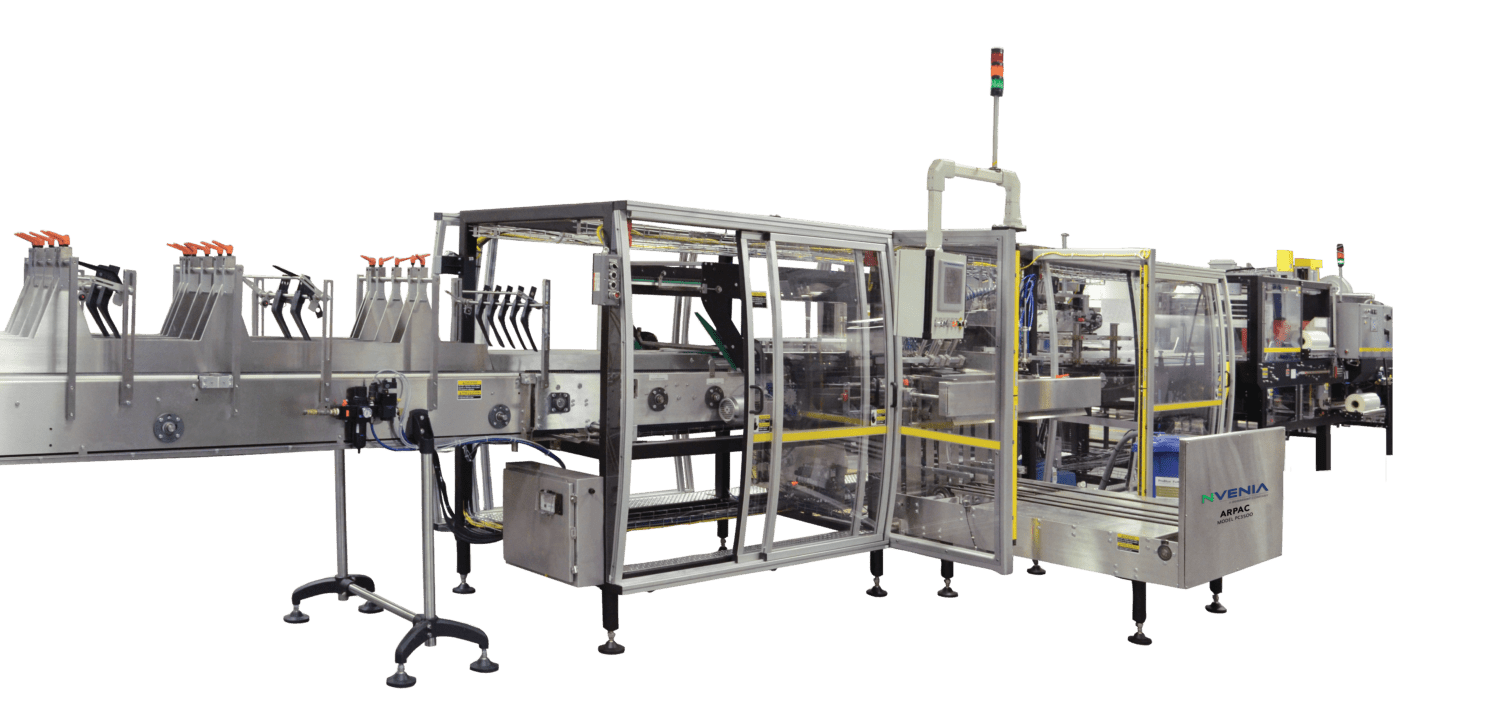

Arpac Brand RTAC Model Pallet Wrapper

Our Arpac Brand RTAC Model is a Heavy-duty Conveyorized Rotary Tower style pallet wrapper, ideal for high speed conveyorized production lines. Like all of our pallet wrappers, the RTAC is constructed of heavy-duty, welded steel structures designed for long life and machine stability. Complete with easy to use Allen-Bradley touchscreen HMI controls, the RTAC is an ideal solution for integrating stretch wrapping into your packaging process.

This model has a unique arm support & drive system that incorporates a precision steel ring for stable, safe, and maintenance-free machine operation. To increase efficiency, the RTAC indexes, automatically wraps, and discharges loads without operator assistance. A dual action cut and wipe arm provides clean cut and positive film tail attachment to the load. In addition to these capabilities, the RTAC Model can be manufactured with several performance enhancements. The optional Pallet Lift Mechanism is used to lift the load in the wrap zone allowing lower film wrap height from the bottom of the pallet. A Top Sheet Dispenser covers the top of the pallet with film to dust-proof or weather-proof the load.

Are you interested in this product?

We are here to help.

Features

Standard

- Heavy-duty reinforced structural steel construction

- Heavy duty conveyors with 2.5″ rollers driven by “loop to loop” ANSI chain for more positive pallet handling

- 4,000 lb. load capacity

- Photo electric load height sensor that detects most dark colored loads

- Photo electric sensors control indexing, position and exiting of wrapped loads

- Positive home position alignment

- Adjustable top and bottom wrap counters (0-7)

- 3 wrap patterns including bypass mode

- Touch screen Allen-Bradley® HMI for machine parameter settings, manual operations and fault diagnostics messages

- Safety photoeye and brake system on the fence and wrap zone immediately stops arm rotation in emergencies

- Safety flashing light informs that machine is in cycle

- Standard 6′ high safety fencing and access door with interlock switch for safe entry into wrapping area

- EZ-LOAD FILM-SAVR Powered Pre-Stretch: up to 300% with minimum neck down

- Film delivery system with 1/2 HP AC motor

- Carriage design allows film to grip pallet 3″ to 4″ from top of conveyor

- Anti-static film rollers

- Automatic film clamp, cut, and wipe assembly with manual override control

- Top film overwrap control feature (TOC)

- Electronic film tension adjustment control

- Analog proximity switch dancer bar control for more reliable film feed speed control & corner compensation

- Variable carriage speed (0-30 FPM)

- UL approved components

Options

- Variable speed chain conveyors

- Pallet Lift Mechanism to allow for lower wrap heights

- Wrap-N-Weigh feature can be integrated into the conveyor

- Roping option with special roping sequences

- Top platen feature for supporting unstable loads during the wrapping cycle

- Top sheet dispenser for extra load protection from the elements

- Remote Start

- Various conveyor heights, forklift bumpers, light curtains, and ramps

- 30″ film delivery system

- Tower extensions to achieve 96″ wrap height

- Film usage monitoring

- Fork truck safety eye prevents conveyor section from running while loading and unloading

- Heat seal tail closure

Standard Specs

Standard Specs

Speed

Up to 100 loads per hour

Conveyor speed: 35 FPM

Arm rotation speed up to 24 RPM

Electrical Power Requirements

220V, 3Ph, 60Hz, 25A, 16.5kW

Compressed Air Requirements

Min Load Dimensions

30″ W x 30″ L x 30″ H

Max Load Dimensions

50″ W x 50″ L x 80″ H Standard, 53″ W x 53″ L x 96″ H Optional

Film Roll Diameter

20″ Standard, up to 30″ Optional

Other Film Specifications

Film pre-stretch up to 300″ with minimum neck down

Machine Length x Width x Height

387″ x 123″ x 138″ (standard tower)