The Duravant family of operating companies serve the food processing, packaging and material handling segments.

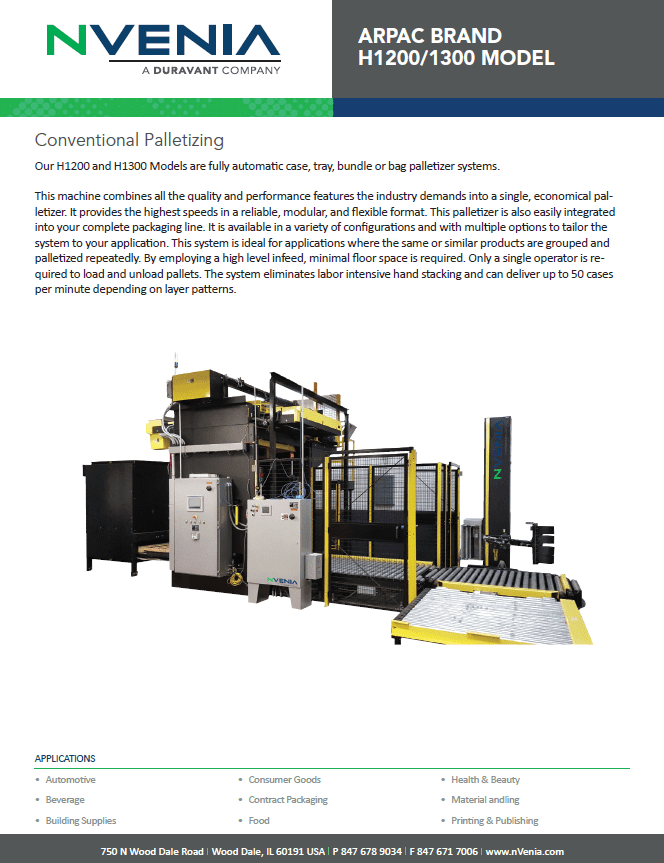

Arpac Brand H1200/1300 Model Palletizer

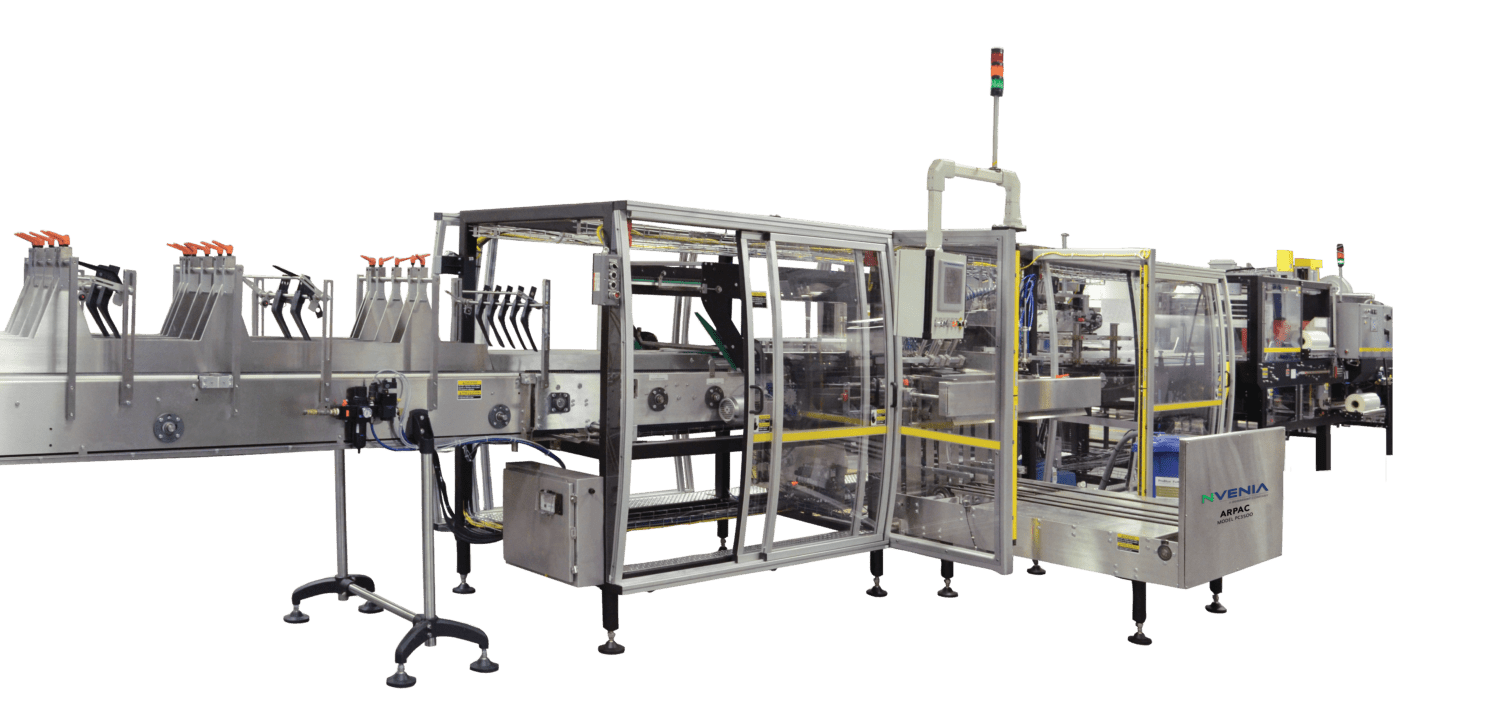

Our H1200 and H1300 Models are fully automatic case, tray, bundle or bag palletizer systems.

This machine combines all the quality and performance features the industry demands into a single, economical palletizer. It provides the highest speeds in a reliable, modular, and flexible format. This palletizer is also easily integrated into your complete packaging line. It is available in a variety of configurations and with multiple options to tailor the system to your application. This system is ideal for applications where the same or similar products are grouped and palletized repeatedly. By employing a high level infeed, minimal floor space is required. Only a single operator is required to load and unload pallets. The system eliminates labor intensive hand stacking and can deliver up to 50 cases per minute depending on layer patterns.

Are you interested in this product?

We are here to help.

Features

Standard

- Up to 50 cases per minute depending on layer pattern

- High infeed occupies minimal floor space

- Multiple layouts to accommodate facility constraints

- Four-corner, chain-driven pallet suspension system supports the heaviest loads

- Extended vertical sides on pallet dispenser for enhanced safety

- Efficient- a single operator is required to load and unload pallets

- Automatic stacking and layer patterns

- User-friendly operation with simple controls

- Allen-Bradley® Programmable Logic Controller (PLC)

- Remote operator controls

Options

- High capacity intermediate layer forming conveyor

- Extra load size capacities for all three dimensions

- Slip sheet and tie sheet dispenser

- Low level pallet/sheet detectors

- Production counters and program controller

- Electronic controls compatible with your plant standards

- Infeed and discharge conveyor systems

- Labels out rotate device

- Palletless construction

Standard Specs

Standard Specs

Speed

Up to 50 cases per minute depending on layer patterns

Electrical Power Requirements

230/460VAC, 3 Ph, 60 Hz, 30A

Compressed Air Requirements

80 psi, 4 SCFM