The Duravant family of operating companies serve the food processing, packaging and material handling segments.

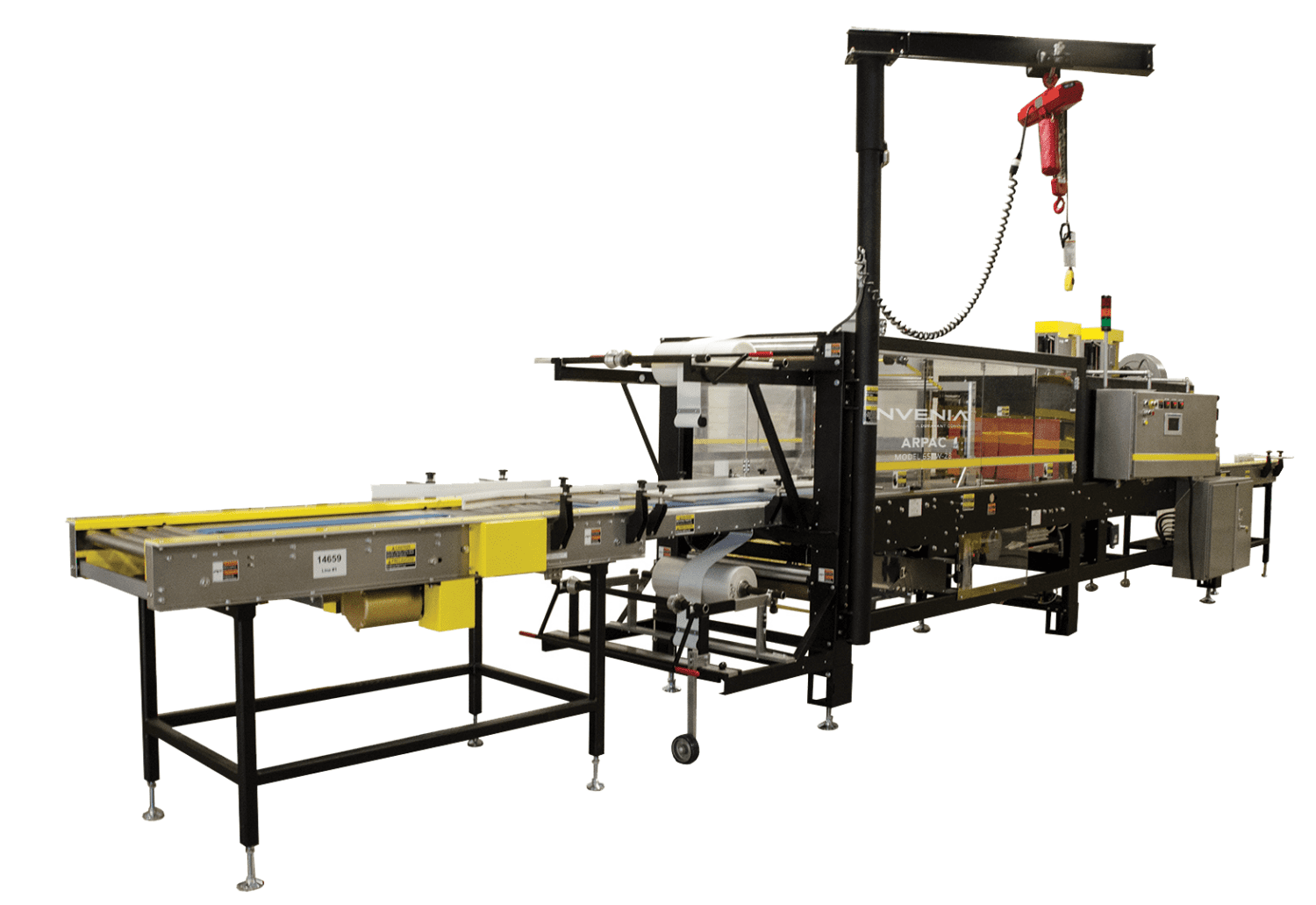

Arpac Brand BPTW Model Shrink Bundling Multipacker

Using single roll print registered polyethylene film, our BPTW Model ensures accurate placement of printed logos, graphics and advertising messages on each bundle with a bullseye enclosure. Print registered film provides an attractive presentation for your retail marketing message at a fraction of the cost of traditional paperboard packaging. The finished package is an easy to carry unitized bundle that is attractive to the end consumer. Servo technology ensures the wrapper provides gentle product handling and precise wrapping. This automatic system paces product, wraps print registered film around the product and shrinks the film to make bullseye style shrink bundles.

Are you interested in this product?

We are here to help.

Features

Standard

- Printed film registration for accurate and repeatable placement of printed graphics

- Heavy-duty frame construction with welded joints for high durability

- Rugged powder coated frame members for long life and wear resistance

- Gentle product handling with servo driven acceleration system

- Servo driven overwrap for smooth and efficient film wrapping

- Servo-driven film feed is low maintenance and can adapt to a wide range

of film lengths (no vacuum) - Side mounted film rack and film splicing bar for quick and easy film changeover with little or no downtime

- Easy machine adjustments for reliable and quick product changeover

Options

- Machine mounted jib crane to facilitate film loading

- Product turning conveyor to provide correct wrapping orientation

Film

- 1.75-2.5 mil low density polyethylene

- Clear or print registered

- 26” maximum width

- 20″ maximum diameter with 3″ core

Product Range

- Minimum product size: 6″ W x 5″ L x 3″ H

- Maximum product size: 20″ W x 12″ L x 12″ H

- Maximum speed: Up to 70 packages per minute

Standard Specs

Standard Specs

Speed

Up to 70 packages per minute

Electrical Power Requirements

480V, 3Ph, 60Hz

Other voltages available on request

Compressed Air Requirements

80 psi, 30 CFM at 50 cycles per minute

Width (across machine)

6” – 20”

Length (flow direction)

5” – 12”

Height Range

3” – 12”

Film Roll Diameter

Up to 20″ with a 3″ core

Film Gauge

1.5 mil to 2.5 mil

Film Type

Low density polyethylene

Other Film Specifications

Clear or print registered