The Duravant family of operating companies serve the food processing, packaging and material handling segments.

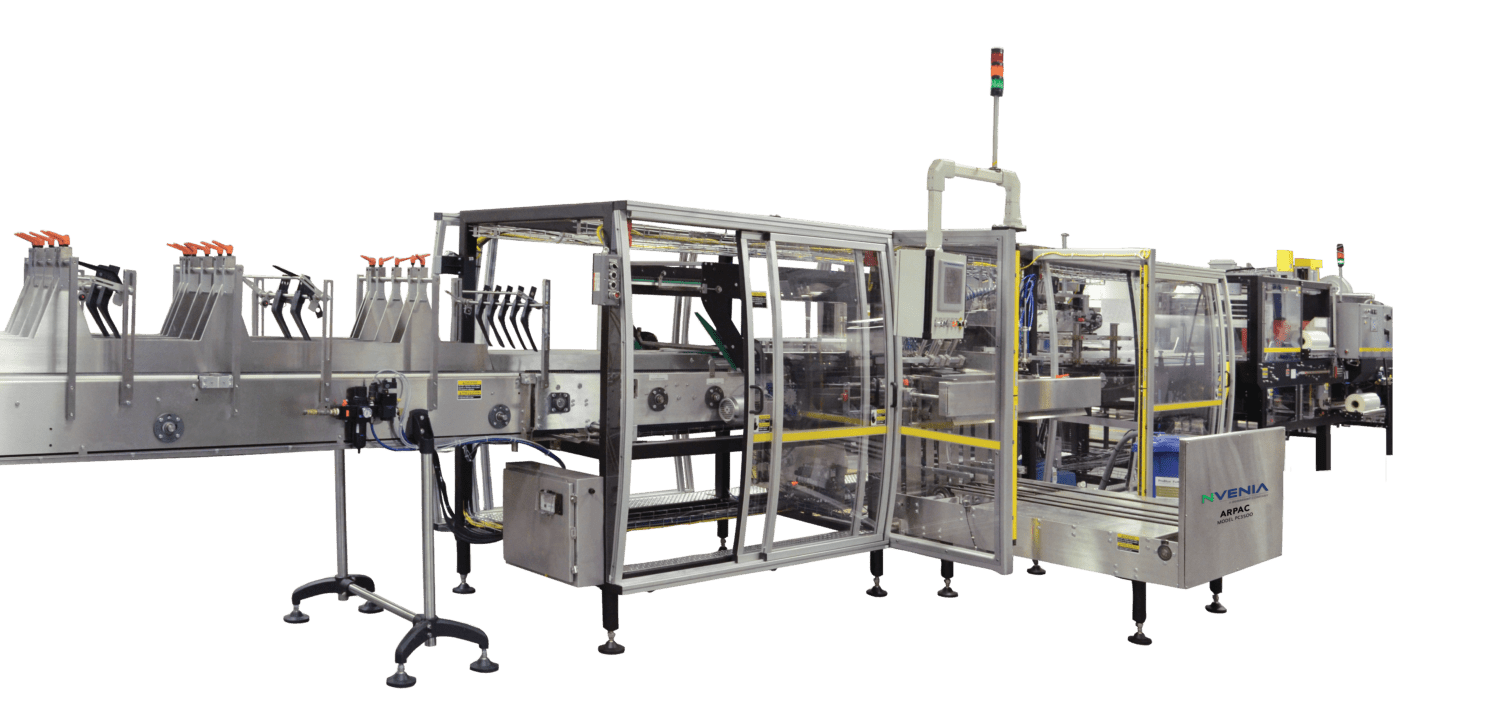

Arpac Brand EWA-C Model Pallet Wrapper

Our Arpac Brand EWA-C Model is an Inline Conveyorized Rotary Tower style pallet wrapper combined with either a drag chain or roller conveyer. Like all of our pallet wrappers, the EWA-C is constructed of heavy-duty, welded steel structures designed for long life and machine stability. Complete with easy to use Allen-Bradley controls, the EWA-C is an ideal solution for integrating stretch wrapping into your packaging process.

A key benefit of this design is that no air is required, which makes this ideal for cold storage areas where air lines would freeze. It also offers a range of options for a variety of applications and load types, including either a drag chain or roller conveyor, cold and freezer packages, and tower and arm extensions for larger load types. Free standing control panels and other NEMA rated enclosures are also available.

Are you interested in this product?

We are here to help.

Features

Standard

- Heavy-duty, welded steel construction (no plastic panels) designed for long life

- Magnetic proximity switches in place of mechanical limit switches

- Long-range photo eye for automatic load height sensing

- Positive home position alignment

- Integrated film clamp

- Automatic indexing

- End pallet stop included

- Chain driven roller conveyor can support up to 4,000 lb.

- Three strand drag chain conveyor can support up to 3,000 lb.

- Adjustable top and bottom illuminated LED wrap counters

- Allen-Bradley® power, control, and safety components

- Allen-Bradley® MicroLogix™ PLC

- Built-in self-diagnostics

- Variable wrap arm speed using 3/4 HP, 90Vdc motor with ANSI 60 chain drive system

- Variable carriage speed up to 21 feet per minute

- EZ-Load® film pre-stretch dispenser for 20″ film rolls

- Dual anti-static film rollers with manufacturer’s lifetime warranty

- Electric clamp, cut, and wipe-down system

- Top film overwrap control feature (TOC)

- Electronic film tension adjustment control on control panel

- Belt lift for quiet operation

- Dual V-belt drive rotating arm

- Dancer bar variable corner compensation

- Flashing safety beacon

- Heavy-duty slewing bearing and NEMA 3 commutator

- NEMA 12 electrical cabinet

- UL/CSA approved components

Options

- Chain driven roller conveyor capable of supporting up to 4,000 lb.

- Three strand drag chain conveyor capable of supporting up to 3,000 lb.

- Tower and arm extensions for wrapping loads exceeding standard machine capability

- 30″ film delivery system

- Cold and freezer packages available

- Free standing control panel

- Other NEMA rated control enclosures available

- Optional input voltages

Standard Specs

Standard Specs

Speed

25-55 loads per hour

Arm rotation speed Up to 15 RPM

Variable carriage speed up to 21 feet per minute

Electrical Power Requirements

230 V, 3 Ph, 60 Hz, 20 A, 2.4 kW

Compressed Air Requirements

None

Min Load Dimensions

53″ W x 53″ L x 24″ H

Max Load Dimensions

60″ W x 60″ L x 80″ H Standard, up to 110″ H Optional

Film Roll Diameter

20″ Standard, up to 30″ Optional

Other Film Specifications

Film pre-stretch capability from 150% to 300% stretch factor (200″ standard)

Machine Length x Width x Height

240″ x 167″ (wrapper only) x 123″ (standard tower)