The Duravant family of operating companies serve the food processing, packaging and material handling segments.

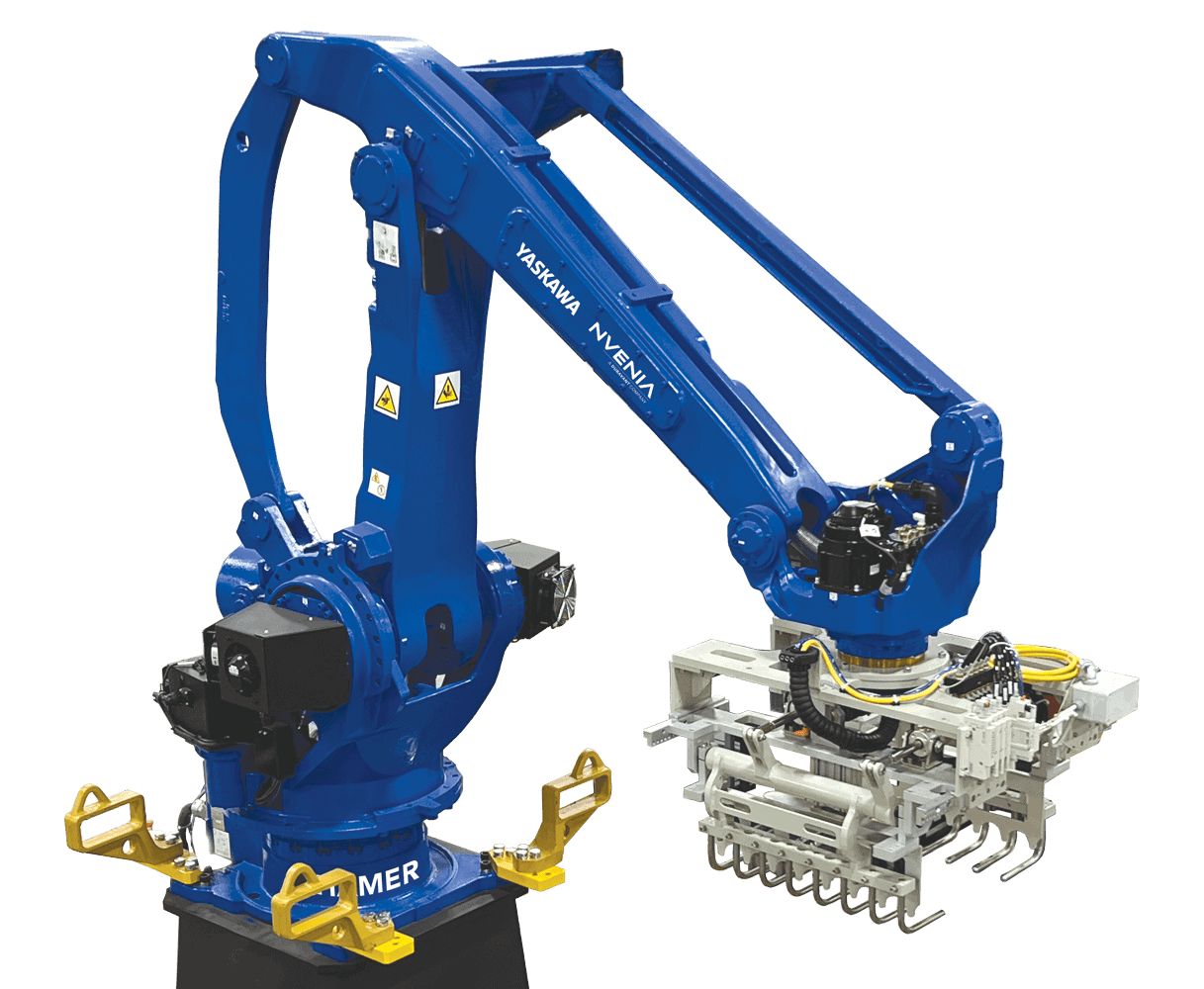

Hamer Brand Basic Robotic Bag Palletizer

The Hamer Brand Basic – Entry Level – Robotic Palletizer features a current generation 5 axis robotic arm. The Basic Model makes semi-automatic or fully automatic palletizing even more affordable for lower production demand applications.

These systems are available in semi-automatic or fully automatic configurations. A semi-automatic configuration describes an operation where bags are fed to the palletizing robot and placed on a stacking station with floor positioned empty pallets. Full pallets are then picked up by fork trucks or pallet jacks for wrapping prior to shipment. A fully automatic configuration features a pallet dispenser, slip sheet dispenser, and automatic full pallet conveyors. This system feeds empty pallets to stacking stations where a robotic arm stacks bags onto the pallet. Once a pallet is completed, it is transported via automatic powered conveyors to an integrated pallet wrapping machine or hooding equipment.

Are you interested in this product?

We are here to help.

Features

Standard:

A wide variety of configurations and system designs are available. An RPM Palletizer System typically includes:

- Semi-automatic configuration with 1 or 2 pallet stack

- Fully automatic configuration with power conveyors

- MPL 100 II, 5 axis, 100KG robotic arm

- DX200 Robot Controller

- Robot mounting base plate/riser

- 28” robot riser

- EasyPic operator software pallet configuration

- MaxPic pallet configuration

- Industrial design End Of Arm Tooling

- ANSI/RIA safety protocols

Options

A wide variety of configurations and system designs are available, including a Palletizer Preventative Maintenance service program.

- EasyPic™ Operator HMI

- Servo chiller for high temperature installations

- Industrial End of Arm Tool options

- Multiple pick points

- Multiple stack points

- Light curtains for continuous operation

Bag Types

For more information on the variety of bags and products we can handle, please contact your Hamer sales representative.

Standard Specs

Standard Specs

Speed

16-18 bags per minute

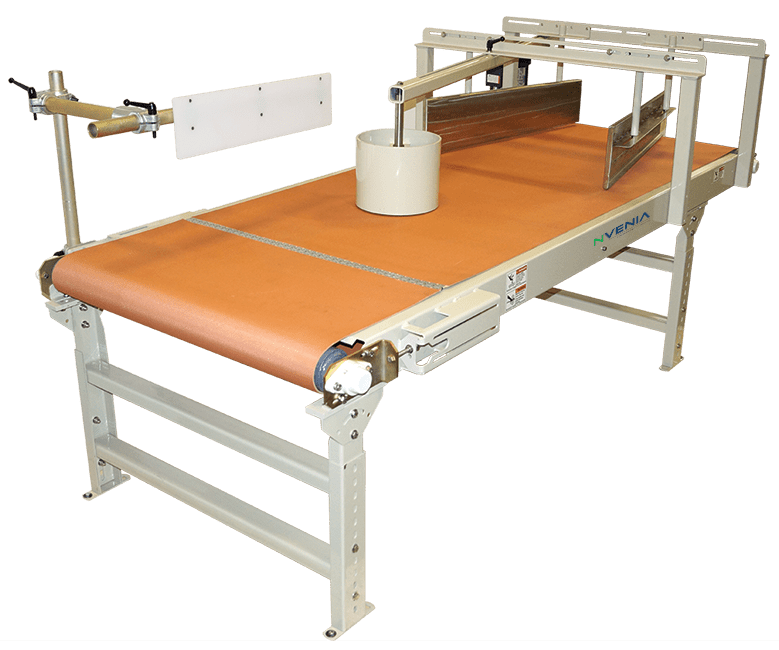

Chain Driven Live Roller (CDLR) Speeds: 60 FPM

Electrical Requirements

460VAC, 3 Ph, 60 Hz

Air Requirements

2-10 CFM @ 80 PSI (design dependent)

Max Bag Weight

60 lbs

End of Arm Tooling

55 lbs (25 kg)

Pallet Type

Standard 48″ x 40″

Pass Height

Automated systems use a standard 18” CDLR Top of Roller pass height