The Duravant family of operating companies serve the food processing, packaging and material handling segments.

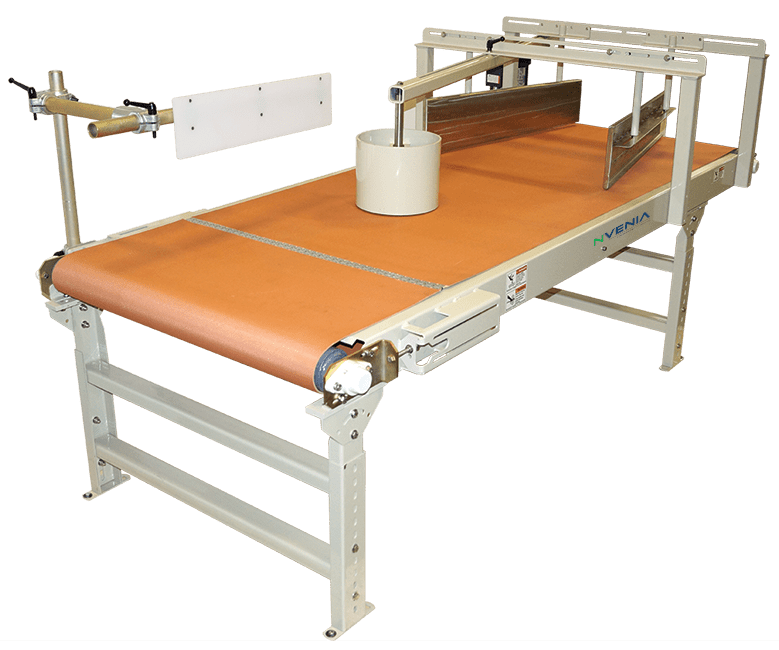

Hamer Brand Model 5100 Bag Flattening Conveyor

Our Hamer Model 5100 Bag Flattening Conveyor is a dual belt system used for bags that require additional conditioning to flatten the bags before palletizing. The 5100 evenly disperses product inside the bag to improve bag handling and pallet build.

Our Hamer Model 5100 is perfect for palletizing operations bagging loose materials such as seed and grain. Two inverted belt conveyors are used to flatten bags for controlled layering. Evenly dispersing product inside the bag minimizes labor by improving bag handling and pallet build. Flattened bags are more symmetrical, allowing them to be stacked quicker and with better precision. They also hold up better and experience less material damage than unflattened bags. An ideal solution for business owners looking to increase automation, this heavy duty model can help minimize labor costs and reduce material damage often caused when unflattened bags are improperly stacked.

Highly robust and easy to integrate, the 5100 can be used with manual or automated bagging lines. Available options include custom lengths, and flat or inclined versions.

Are you interested in this product?

We are here to help.

Features

- 3 ply non-slip belting

- Powered top flattening conveyor

- Manual adjustment of top conveyor

- 3/4 HP, TEFC motor

- 5.5″ x 1.5″ x 10 gauge formed channel side frames

- Powder coated frame

- 1″ to 10″ flattening height top conveyor adjustment

- On/Off Controls with mushroom E-Stop

Standard Specs

Standard Specs

Length and Width

Standard lengths of 8′ and 10′

30″ wide (27″ belt width)

Speed

Up to 100 FPM

Electrical Requirements

230/460 VAC, 2.7/1.35 A, 3 Ph, 60 Hz

Air Requirements

None required

Accessories

Accessories

OPTIONS:

- Custom lengths

- Stainless steel fastners

- Bag end transition roller

- Roller conveyor/stacking table