The Duravant family of operating companies serve the food processing, packaging and material handling segments.

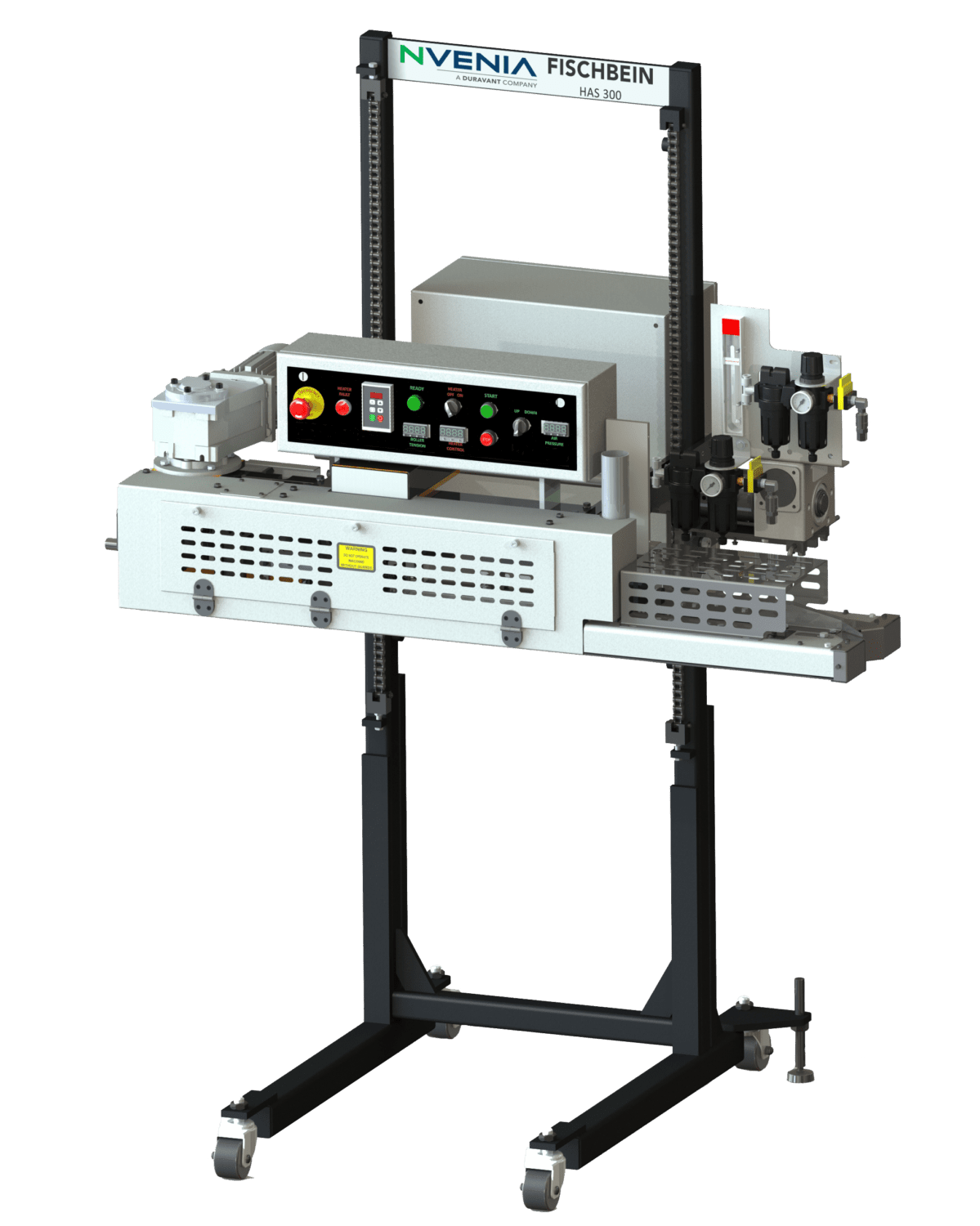

Fischbein Brand Double Roll Closer – DRC 300

The Fischbein Brand DRC 300 Double Roll Closer seals multi-wall, flush-cut paper bags weighing up to 50 pounds, at production rates up to 75 linear feet per minute. The DRC 300 automatically trims the top of the bag, makes a single precise fold, applies hot melt adhesive, then makes a final second fold. The patented breakaway design eliminates costly downtime caused by bag jams, while allowing easy cleaning and service of the bag folder.

Are you interested in this product?

We are here to help.

Features

Standard

- Closes multi-wall paper bags.

- Spiral glide folder technology creates bag closures that are consistent, reliable and attractive.

- Patented breakaway design eliminates costly downtime caused by bag jams while allowing easy cleaning and service of the bag folder.

- Digital controls and readouts

- Safe and easy to use control panel with digital temperature control and display keypad for variable speed control, and dual emergency stop buttons.

- Right to Left operation

- Dynatech Hot Melt Adhesive Applicator

- Dual Knife Bag Top Trimmer

- Dust tight, NEMA 12 rated electrics

Options

- Additional motor starter and contactor for conveyor

- Left to right operation

- CR Plus 2 part corrosion resistant powder coat finish

- Nordson brand hot melt application system

- Wide fold for larger bags – Model 300 Plus

- 460 and 575 VAC

Bag Types

Open mouth flat or gusseted multi-wall paper bags

Bag Face Width

Minimum 5 in (12.7 cm)

Free Bag Top

Minimum 6 in (15.2 cm) – standard fold Minimum 7.5 in (19 cm) – wide fold

Standard Specs

Standard Specs

Dimensions

W 82 in (208 cm) x D 46 in (117 cm) x H 54-85 in (137-216 cm)

Speed

Up to 75 linear feet per minute

Electric

230V – 3PH – 50/60Hz, 24 VAC

Air

90 PSI, 8 SCFM