The Duravant family of operating companies serve the food processing, packaging and material handling segments.

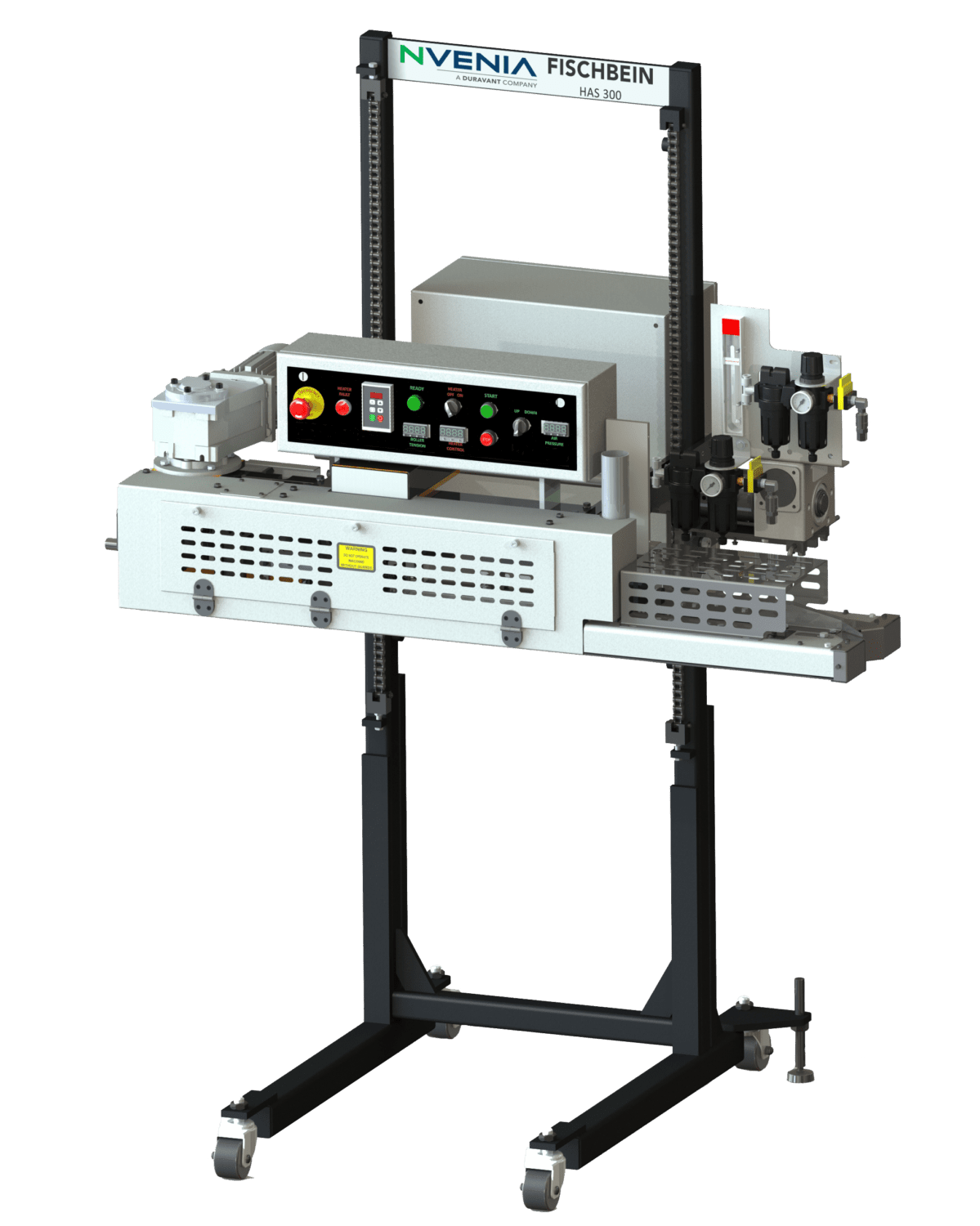

Fischbein Brand Hot Air Sealer – SH 2000

Our Fischbein Brand SH 2000 Hot Air Sealer is an advanced hot air bag sealing system that seals a variety of polyethylene bags and pouches for applications in the food, medical and chemical sectors. Easily adjustable controls for the heaters, air flow, and variable speed drive ensure efficient heat transfer and sift proof sealing. Increased capacity delivers faster product changeovers and less downtime. The SH 2000’s proven hot air technology eliminates the need for traditional sealing bands and lowers maintenance costs.

Are you interested in this product?

We are here to help.

Features

Standard

- Increased heater airflow resulting in faster operating speeds and increased productivity

- Low-profile infeed ensures correct bag presentation

- Adjustable wheel setup for fast product changeover

- High-efficiency heaters accommodate a variety of bag types and sizes

- Electric height-adjustable column

- NEMA 12/IP54 rated electrical

Options

- Bag-top trimmer

- Airwash bag-top cleaner

- External vortex bag-top cooler

- Wash-down version

- Crimp wheels

- Extended infeed system

- Extended reach (cantilevered) sealer head (used for wide diameter sealing conveyors)

Bag Types

Thermo-weldable, pillow style, polyethylene bags and pouches

Bag Thickness

Max. 12 mils

Standard Specs

Standard Specs

Dimensions

40.5″ (102.8 cm) L x 28″ (71.1 cm) D x 65″ (165.1 cm) H

Speed

20.3 to 46.3 linear feet per minute

Electric

230V – 3 Ph-50/60Hz

Air

No Air