The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Arpac Brand BPSW Model Shrink Bundling Multipacker

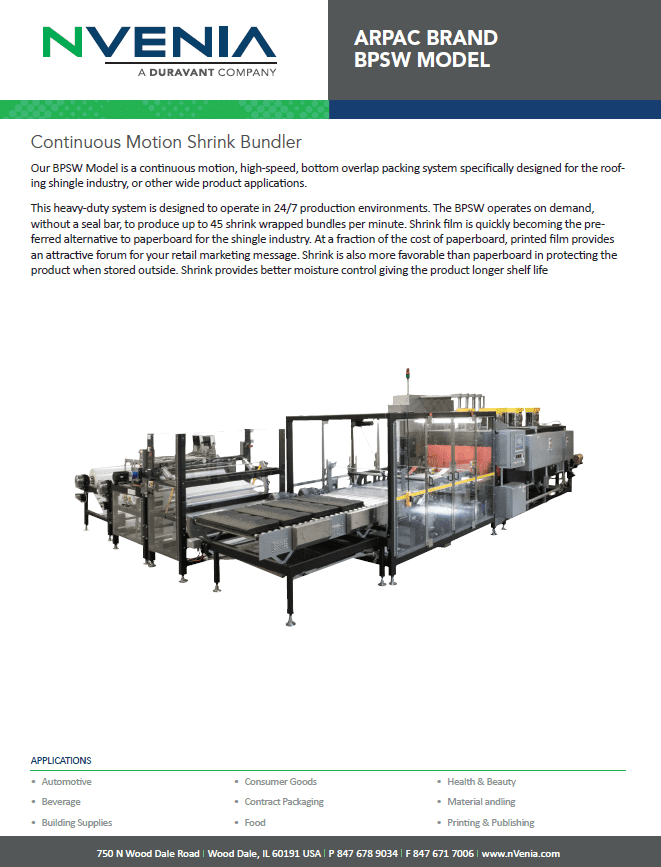

Our Arpac Brand BPSW model is a heavy duty system designed to operate 24/7 in tough and gritty production environments – specifically the roofing shingle industry. The BPSW operates on demand, without a seal bar, to produce up to 50 shrink wrapped bundles per minute. At a fraction of the cost of other solutions, film provides a protective and aesthetic solution for your packaging needs.

Are you interested in this product?

We are here to help.

Features

Standard

- Servo controlled precise overwrap system

- A unique film feed system dispenses, on demand, single sheets of film cut to size from a single print registered film roll

- Dual side mounted film rack with splice bar and spare film roll to reduce down time

- Integrated shrink tunnel with a triple turbo cooling unit expedites film curing and stabilizes product in the package as it cools

- Tough polyurethane belt on acceleration and overwrap conveyors

- Uses clear or print-registered polyethylene shrink film

Options

- Cooling conveyor with reject station

- Electro polished or Teflon coated tunnel belt

- Integrated printer

- Redundant HMI

- Central lubrication station

- Dual overlap track for bundles > 14″ L

- Additional static bars

- Contact nVenia or your local sales representative for all available options

Standard Specs

Standard Specs

Speed

Up to 45 packages per minute

Electrical Power Requirements

460VAC, 3Ph, 60Hz, 250A

Compressed Air Requirements

80 psi, 60 CFM

Width (across machine)

30″ – 42″

Length (flow direction)

7″ – 14.5″

Height Range

2.25″ – 4″

Film Roll Diameter

Up to 24” with a 6″ inner core

Film Thickness

1.5 mil to 4.0 mil

Film Type

Low density polyethylene

Other Film Specifications

Clear or print registered, single wound