The Duravant family of operating companies serve the food processing, packaging and material handling segments.

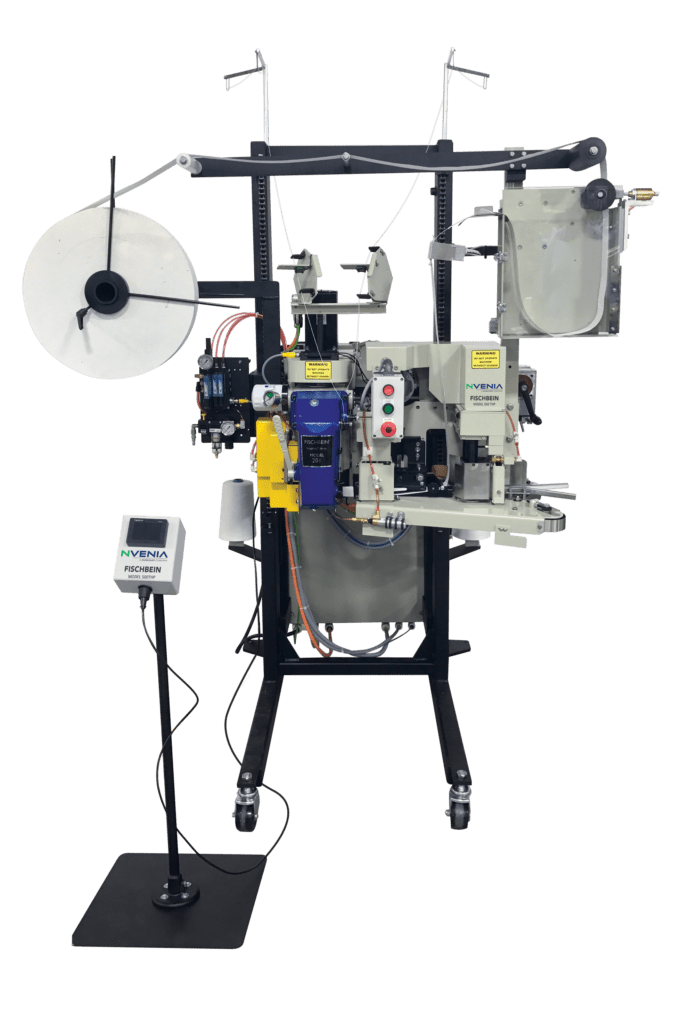

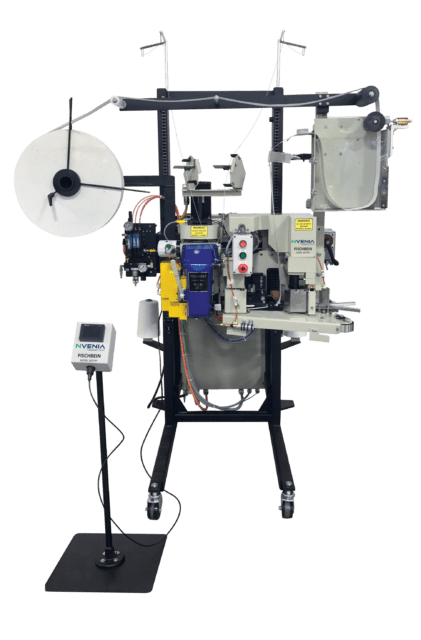

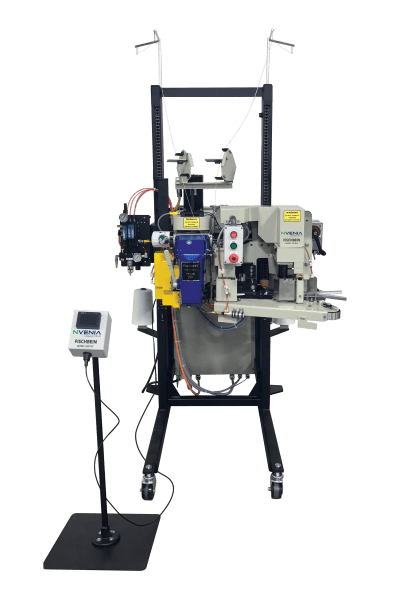

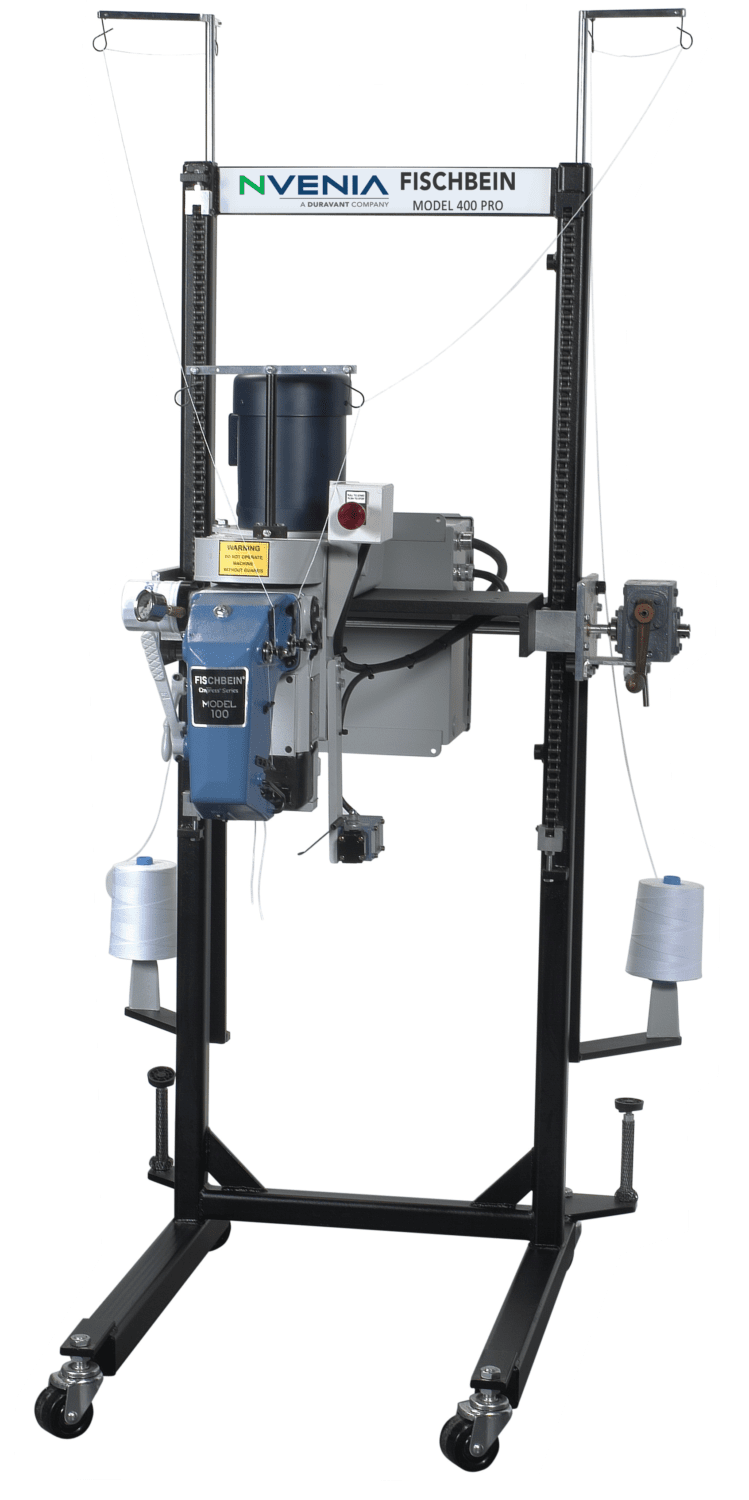

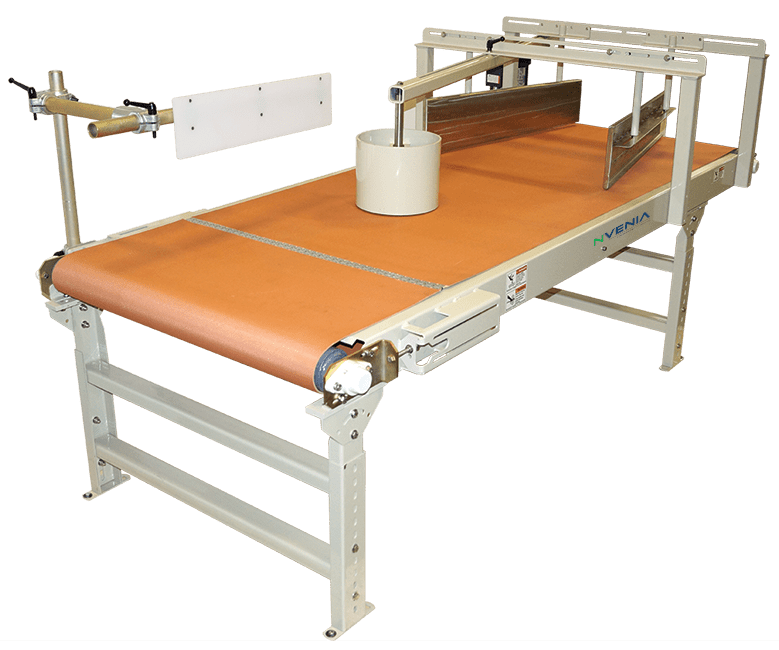

Fischbein Brand Tape Sew System – Model 501T

The Fischbein Brand 501T Tape Sewing System produces highly attractive crepe tape sewing closure for multi-wall paper and laminated woven polypropylene open mouth bags. This versatile, high production tape sew system features an all-new operator HMI and an improved powered crepe tape feed system. Operating at speeds up to 75 linear feet per minute, the Model 501T is safe, easy to use, and easily integrated into any automated bagging line. Powered by an all-new servo motor to drive the sewing head, and with VFD control for the infeed, it provides a fully synchronous sewing system solution.

Are you interested in this product?

We are here to help.

Features

Standard

- Closes a variety of bags including flat and gusseted multi-wall paper, and woven polypropylene bags.

- All new intuitive HMI interface allows setting of various run parameters, error reporting and maintenance reminders.

- PLC and servo motor eliminates the need for a clutch/brake.

- New Servo motor with dedicated servo drive; and VFD controlled infeed, with built-in “Safe Torque Off” feature

- Synchronized timing belts ensure consistent, drift-free control.

- Improved powered crepe tape feed system, easy to adjust infeed, and improved thread control.

- Bag Top Trimmer specifically designed with quick change, long-life blades that ensure thousands of hours of trouble-free operation.

- Heavy duty Dura Tape and Thread clipper

- Tape Sew Sensor Package for thread break, tape break and oil detection (with parameters set from HMI)

- With its self-lubricating system, the Empress Sewing head delivers trouble-free smooth performance with low vibration.

- Needle cooler

- New more durable and stable sew stand with improved thread control and reduced vibration

- Compact pedestal design that is fully mobile and features a manual height adjustable sewing line that ranges from 28 to 60 inches high.

- 24 VDC controls for safe, low voltage troubleshooting

- Dust tight NEMA 12 electrics

Options

- Various infeed lengths

- Motorized Height Adjustment

- Motor starter and contactor for conveyor

- Ink Jet Printer

- Tape contact coder

Bag Types

Multi-wall paper and laminated woven polypropylene open mouth bags

Bag Thickness

Maximum 12 mils

Free Bag Top

Minimum 6 in (15.2 cm)

Standard Specs

Standard Specs

Dimensions

46″ (147 cm) L x 41″ (104 cm) D x 78″ (198 cm) H

Speed

Up to 75 linear feet per minute

Electric

230/380/460 VAC – 3 PH – 50/60 Hz

Air

90 PSI, 15 SCFM