The Duravant family of operating companies serve the food processing, packaging and material handling segments.

The Right Conveyor for Any Industrial Bagging Application

05/04/2018

For decades, nVenia’s HAMER Brand has been building high quality, industrial bag handling conveyors for diverse bagging applications. With over 700 industrial systems running worldwide, no one knows bag conveyance better.

Our selection of bag handling, conditioning and transfer conveyors, make us your one-stop shop for all bagging conveyor requirements.

| The Hamer Model 4000 Upright Bag Conveyor is used when hand bagging with a volumetric filler, net weigh, or gross weigh scale. | |

| The Hamer Model 4200 Knock down/Turning Bag Conveyor is used to turn and position bags for “butts forward” orientation for manual or automated bag palletizing. | |

| The Hamer Model 4300 Belt Power Curve Bag Conveyor is used to transport and turn bags around a 90 degree curve. | |

| The Hamer Model 5000 Bag Stacking Conveyor is an incline/stacking conveyor that includes a gravity roller conveyor and stacking table to deliver bags at a comfortable height for manual palletizing. | |

| The Hamer Model 5100 Bag Flattening Conveyor is a dual belt system used for bags that require additional conditioning to flatten the bags before palletizing. | |

| The Hamer Model 5200 Bag Kicking Conveyor transfers bags at a 90 degree angle quickly and efficiently. | |

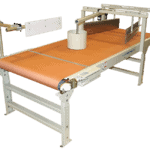

Hamer Brand Model 5300 Belt Over Square Roller Bag Conditioning Conveyor |  | The Hamer Model 5300 Belt Over Square Roller is a bag conditioning conveyor designed for use when products are not suitable for a standard bag flattening conveyor. |

All our bag conveyors are built tough for long life in any plant environment. Heavy gauge steel, oversized motors and drives, heavy duty bearings with easy access grease ports, all stainless-steel hardware and powder-coated finishes all make our line of conveyors the best in our class.

Offered in many lengths, with height adjustment, controls, and power options, our conveyor solutions can improve virtually any bagging production line.