The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Blog

Explore a variety of packaging industry thought leadership pieces from our internal subject matter experts, read compelling case studies, hear from our service techs about helpful maintenance tips and tricks and more here in the nVenia Blog. Do you have a question you would like answered? Or a subject matter in the packaging industry you would like to learn more about? Let us know!

Bagging Commercial or Industrial Fertilizer? Get the Right Band Sealer

06/26/2019

Care Tip – How To Replace The Upper Cross Seal Bar Blade

05/29/2019

Pet Food Bagging Industry Gets Growth Boost

05/10/2019

Preventive Maintenance Checklist – Horizontal Form Fill Seal

04/19/2019

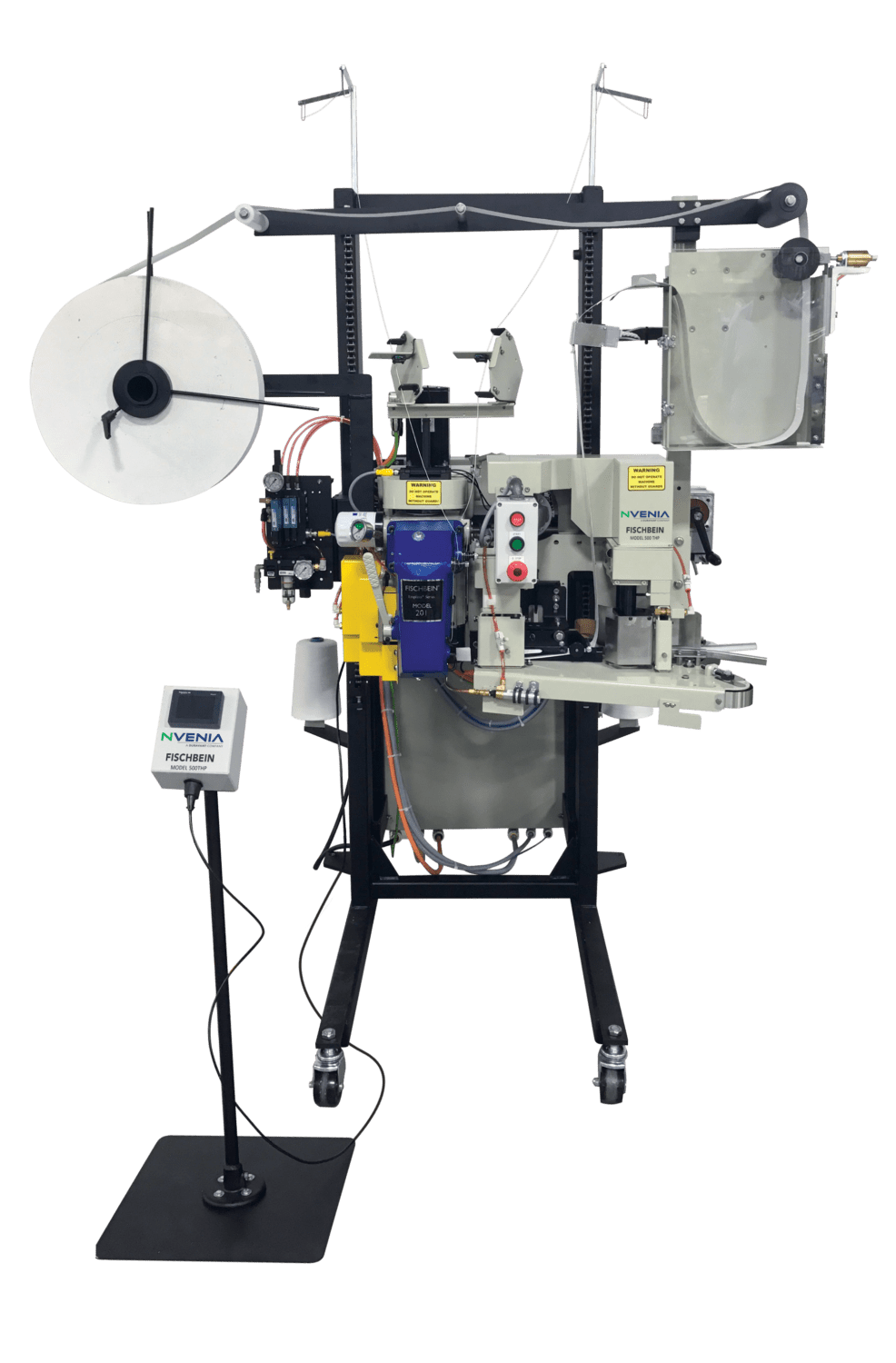

FISCHBEIN Brand Industrial Sewing Thread: Specifications and Accessories

04/05/2019

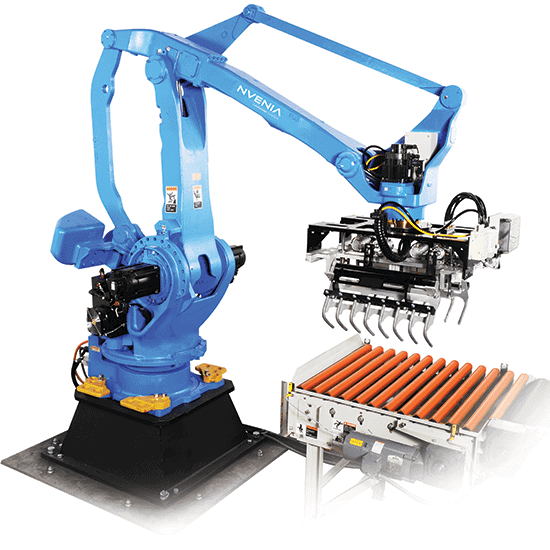

The Future is Now: Robotic Palletizing

03/11/2019

Automated Bagging Operations and Real World Solutions

03/04/2019

Sewing Automation for High Production Packaging Lines

02/22/2019

The Industry Workhorse in PBOM Bag Closers

02/15/2019

Delivering Continuous High-Efficiency Band Sealing

02/01/2019

Setting Standards in Produce Packaging Accuracy and Speed

01/11/2019

Preventative Maintenance Steps for HAMER Brand 100GW Gross Weigh Scale

01/08/2019