The Duravant family of operating companies serve the food processing, packaging and material handling segments.

How to Level and Center a Pinch Bag Closer and Pinch Inner Liner Sealer

06/19/2018

The quality of PBOM bag seals depends on a number of factors. The most basic of these factors is whether the bag is being fed into the machine correctly.

When first setting up a Pinch Bag Closer (PBC) or Pinch Inner Liner Sealer (PILS) for operation they must be properly placed vertically and horizontally in relation to the conveyor system. This is referred to as “Leveling” and “Centering.”

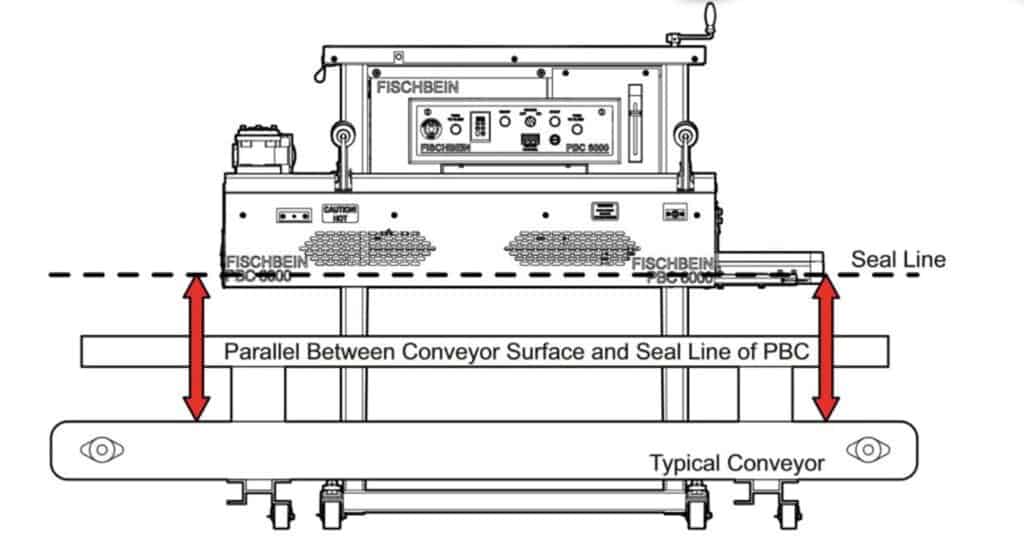

Leveling

To maintain an even fold on the top of the bag, the sealing operation of the machine must run parallel to the conveyor. To check this, measure the distance between the bottom of the carry through belts and the surface of the conveyor belts. This distance should be the same at both the input and output ends of the machine. If there is a significant difference, the bag seal will be uneven from leading to trailing edge of the bag. Make the necessary adjustments to achieve a parallel and straight seal line.

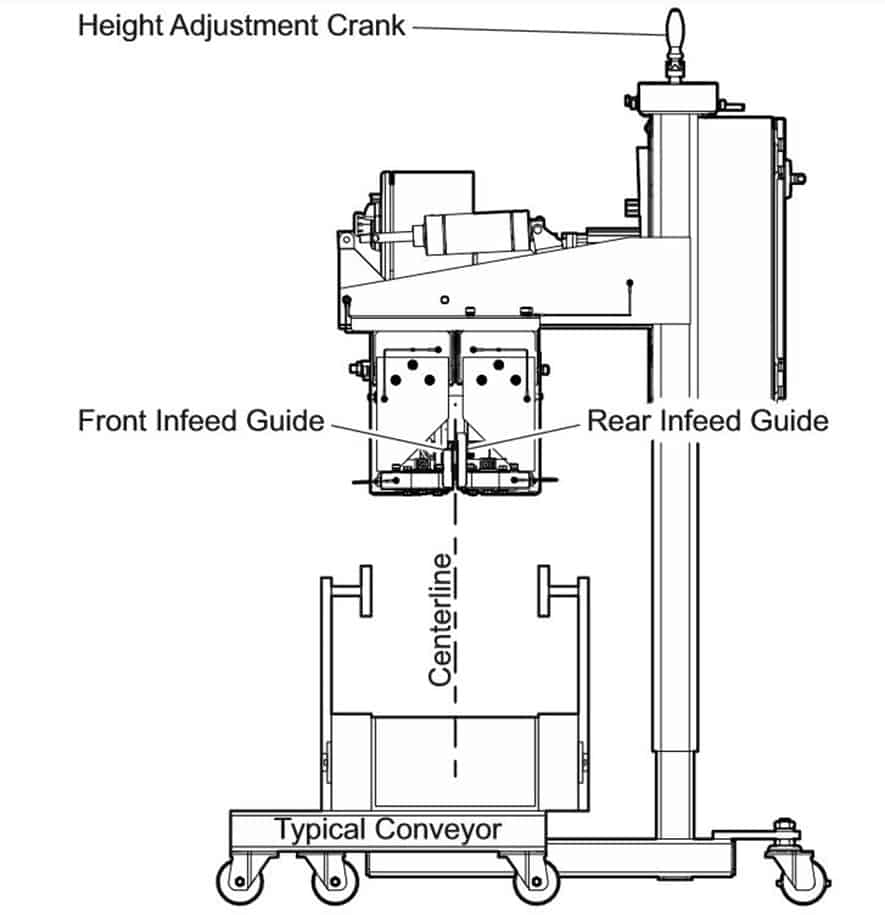

Centering

There are two conditions to satisfy the centering required for a good seal.

The first is where the two carry through belts come together to grasp the bag top. This point must be centered above the middle of the conveyor (i.e. the center line of travel for the bag’s path). If a bag enters the system too far toward the back or front of the machine, the bag may not enter the system straight (affecting seal quality) or the bag may be tilted too far and tip over. If the bags are being fed into the system manually, the operators should be careful to center the bags between the carry through belts. For automated systems, the machine can easily be moved after unlocking two rear casters.

The second condition involves centering the bag top vertically with the carry through belts. The height adjustment on the machine is used to bring the machine’s creaser wheel (the device used to create the crease-line for the bag fold) to the correct elevation with the entering bags.

To determine the correct height:

- Reform the bag and then raise or lower the machine to where the poly thru paper heater bars will seal the inner liner at the bag manufacturer’s suggested height.

- "Free top" is the term used to describe the distance between the top edge of the unfolded bag and the top surface of the product in the bag. For best results PBC and PILS machines require a free top of 6 inches (153mm) for standard size folds and greater than 6 inches for wider folds. Using a shorter free top may cause the bag to bulge and be torn by the shrouds.

- Allow a filled bag sample to come up to the infeed on the machine and then stop the conveyor system. Note the location of the glue line on the bag top. The bottom edge of the glue line must be just above the creaser wheel. It can be a little higher, but the crimp should be made below the bottom of the glue edge.

Following these best set up practices when sealing PBOM bags on Pinch Bag Closers and Pinch Inner Liner Sealers will ensure dependable results and maximum performance.