The Duravant family of operating companies serve the food processing, packaging and material handling segments.

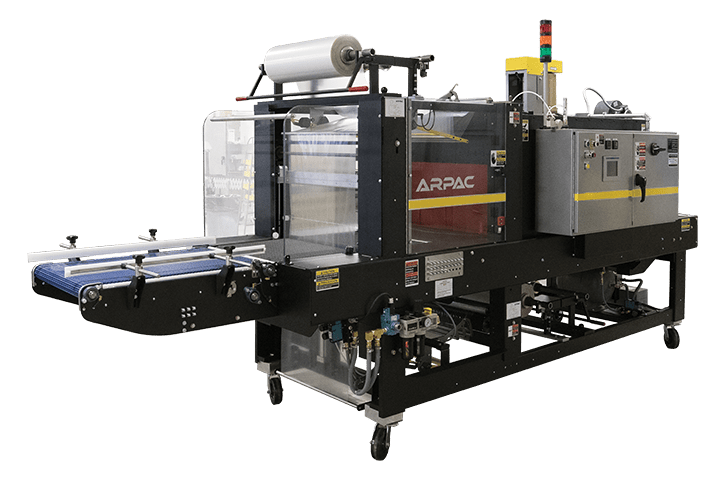

Arpac Brand Sidewinder Model Pallet Wrapper

Our Arpac Brand Sidewinder Model is a Semi-Automatic Turntable style pallet wrapper designed to maximize stretch film usage while ensuring the very best load unitization with up to 6,000 lb. capacity (4,000 lb. standard). Like all of our pallet wrappers, the Sidewinder Model is constructed of heavy-duty, welded steel structures designed for long life and machine stability. Complete with easy to use Allen-Bradley touchscreen HMI controls, the Sidewinder is an ideal solution for integrating pallet wrapping into your packaging process.

This model is available with a high profile turntable for forklift loading, and low profile turntable for pallet-jack loading. It can be customized with extended towers for taller loads, and split frames for odd-sized and larger loads. This system is also available with a 30″ film carriage and dual turntables for greater throughput, cold and freezer packs for reliable operation in extremely harsh temperatures, and a pneumatic roping device for additional load support.

Are you interested in this product?

We are here to help.

Features

Standard

- Heavy-duty, welded-steel construction (no plastic panels) designed for long life

- Long range photo eye for automatic load height sensing

- Adjustable top and bottom illuminated LED wrap counters

- Allen-Bradley® power, control, and safety components

- Allen-Bradley® MicroLogix™ PLC

- ANSI 50 turntable chain drive system

- Cycle pause feature

- Manual jog control for turntable

- Two available wrap patterns

- Top film overwrap control feature (TOC)

- Electronic film tension adjustment control on control panel

- Independent up and down film carriage controls with jog up/down switch

- Dual chain film carriage lift

- Automatic film tension control

- EZ-Load film pre-stretch dispenser for 20″ film rolls

- Dual anti-static film rollers with manufacturer’s lifetime warranty

- Dancer Bar Variable Corner Compensation

- UL/CSA approved components

Options

- Extended film towers for wrapping tall loads exceeding standard machine capability

- 6,000 lb. load limit and large diameter turntables available

- Split frame construction to increase film tower clearance for oversized loads

- Extended umbilical cords for split-frame option

- Cycle counter

- Foot pedal control

- Remote Start

- Bottom rollover Bar

- Dual turntable

- Integrated scale and printer available

Standard Specs

Standard Specs

Speed

Up to 12 RPM rotating table can deliver 25–40 loads per hour

Variable carriage speed up to 21 FPM

Electrical Power Requirements

120 VAC, 1 Ph, 60 Hz, 12A

Compressed Air Requirements

None

Turntable Dimensions

Low Profile: 60″ Diameter Standard

72″ Diameter Optional

90″ Diameter Optional

High Profile: 50″ Square Standard

70″ Square Optional

50″ x 90″ Rectangular Optional

Load Height Range

Film Roll Diameter

20” Standard, up to 30″ Optional

Other Film Specifications

Film pre-stretch capability from 150% to 300% stretch factor (200% standard)