The Duravant family of operating companies serve the food processing, packaging and material handling segments.

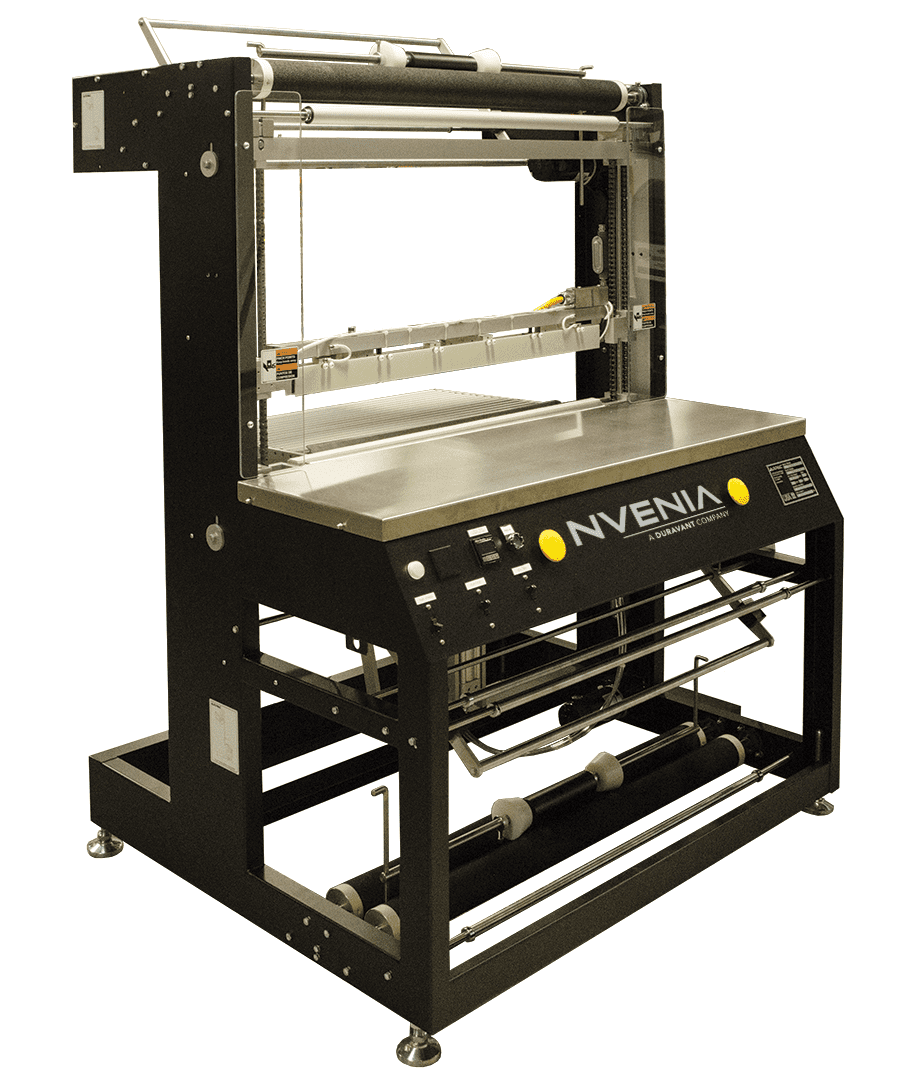

Arpac Brand HVP Model Shrink Tunnel

Our Arpac Brand HVP Model tunnel features a COHRlastic belt designed to produce complete, uniform shrink. Heavy duty blowers create a high velocity recirculation air system that ensures a contour fit and controls the location of seals by forcing hot air to all points and surfaces of the package.

Hot Plate Shrink Tunnels produce a complete and uniform shrink in most high speed wrapping applications by pulling seal lines to the bottom or sides of the package. Typical applications include pizzas, stationery, greeting cards and calendars.

These tunnels are equipped with thermocouple temperature controls, solid belt conveyors, calrod heating elements and UL listed control panels. Tunnels are available in either single or dual zones and are offered with a powder coat paint or stainless steel finish.

Are you interested in this product?

We are here to help.

Features

Standard

- Powder coat finish that provides a durable scratch resistant surface and prevents corrosion

- Trouble-free user-friendly controls assure optimal operation

- Calrod heating elements

- Variable speed conveyor ensures uniform shrink and is adjustable to meet production requirements

- Recirculating heating system consumes less electrical energy by minimizing heat loss

Options

- Hot plate under conveyor belt for additional heat control

- Turbo cooling for product shrink assist

- Spring loaded side compression rollers at discharge of tunnel

Chamber Size

HVP4/488

- 20″ H x 40″ W x 60″ L (Total length 83″)

Standard Specs

Standard Specs

Electrical Requirements

240VAC, 3Ph, 60 Hz, 52 A

Air Requirements

No air required

Conveyor Speed

0 to 85 FPM

Machine Dimensions

61″ W x 96″ L x 83″ H

Shipping Weight

~1500 lbs