The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Archives: Blog

Packaged Ice Palletizing Case Study: Triangle Ice

03/07/2017

Pellet Fuel Bagging Case Study: Marth Wood Products

03/07/2017

Animal Feed Case Study: Form-A-Feed

02/01/2017

Fertilizer Bagging Case Study: American Plant Food Corporation

01/31/2017

Lawn and Garden Bagging Case Study: Markman Peat Improves Efficiency with Automation

01/20/2017

Chemical Bagging Case Study: Caspian Sulphur

01/20/2017

Chemical Bagging Case Study: CRI Catalyst Company

01/20/2017

Animal Feed Bagging Case Study: Kent Nutrition Group

12/01/2016

Industrial Film & Bag Producer Partnerships

10/28/2016

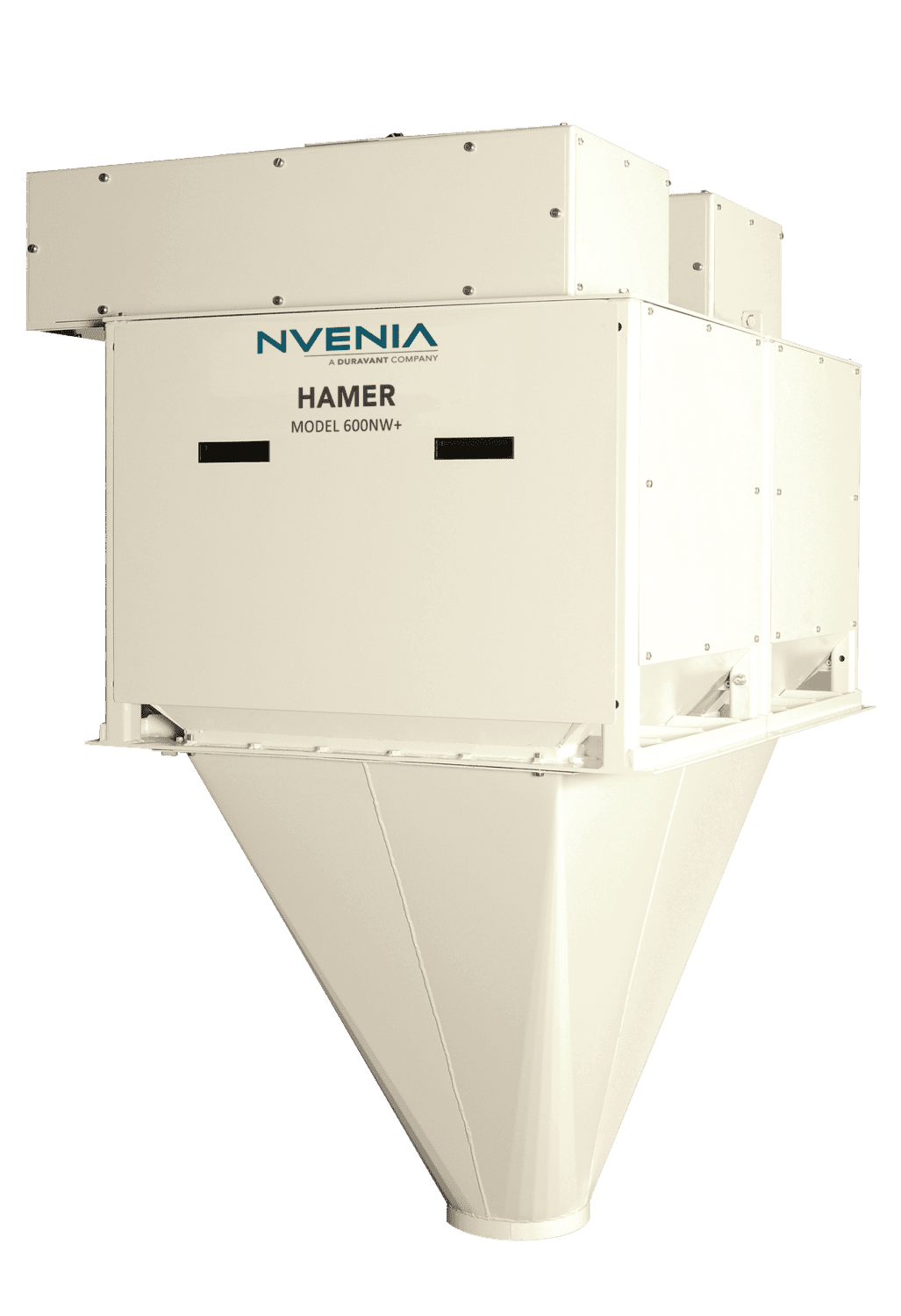

How to Determine The Correct Net Weigh Scale Feeder For Your Material

10/04/2016

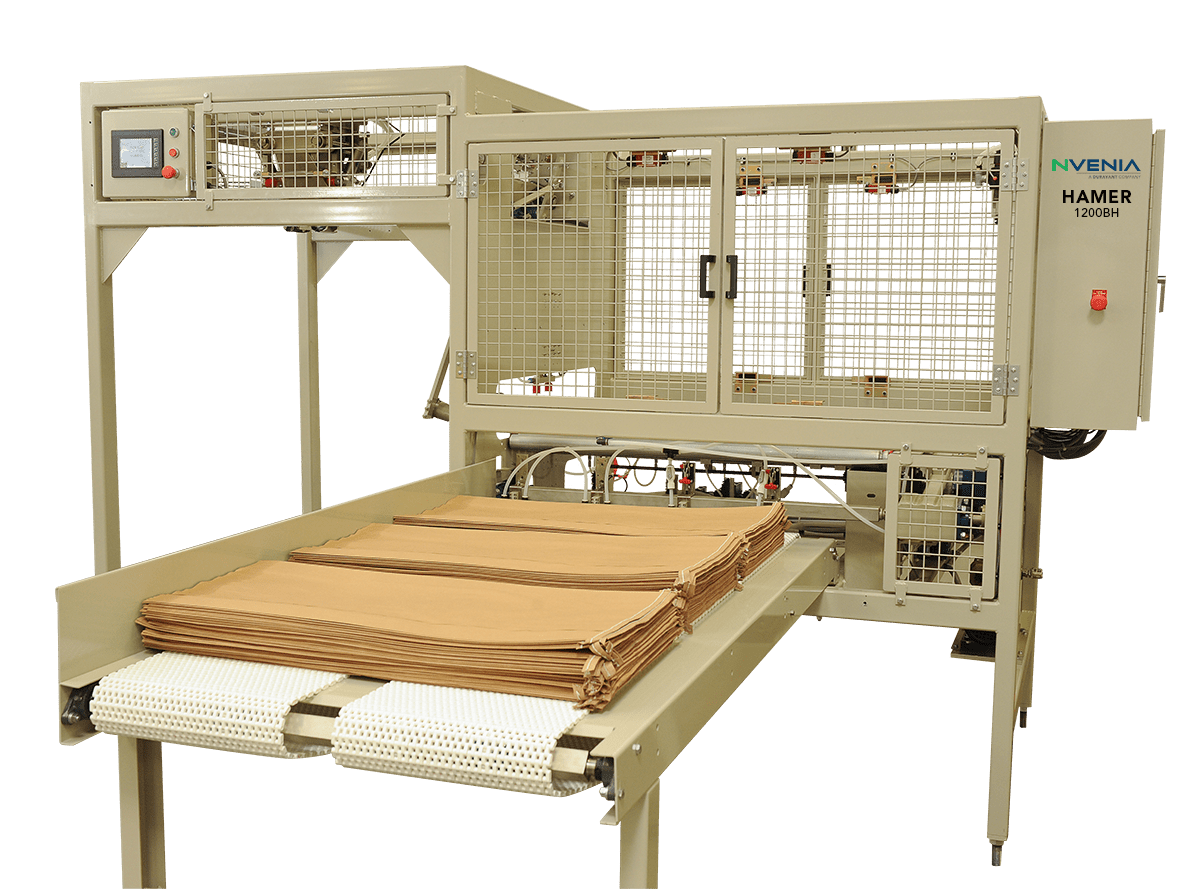

Innovative Upright Bag Conveyor Design Maximizes Production in Feed and Seed Plants

08/15/2016

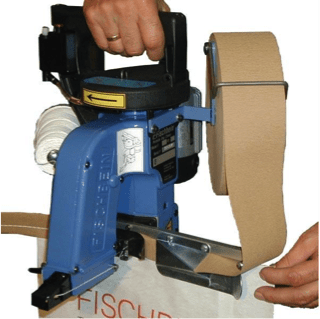

Fischbein F-Series Portable Bag closer: Unbeatable For Quality and Durability

08/10/2016