The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Archives: Blog

Considerations to Make When Buying a Pouch Machine

09/29/2017

The Benefits of Investing in a Bagging Machine

09/26/2017

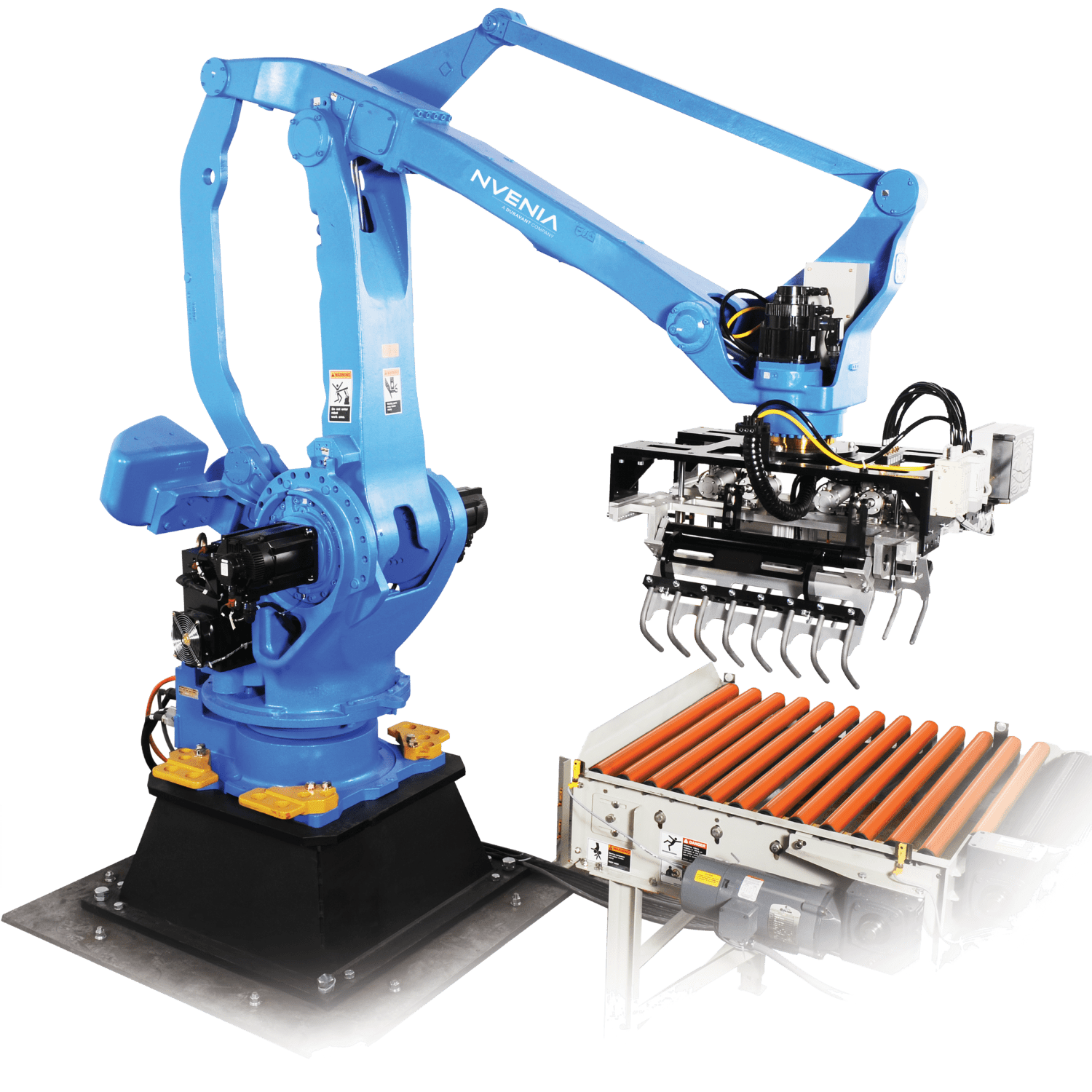

Know Your Robotic Palletizing Supplier

09/11/2017

Optimize Your Packaging System with the Correct Bucket Elevator

08/23/2017

Important Business Benefits of a Multi-Head Weigher

08/16/2017

Corrosion Resistant Net Weighing Solutions for Chemical Bagging Lines

07/31/2017

Using the SB 3000 Band Sealer for Resealable Flexible Food Packaging

07/21/2017

Flour Producer Modernizes Milling Operations with FISCHBEIN Brand Equipment

06/09/2017

Effective Filling Technologies for Bagging Growing Media

05/09/2017

The nVenia FISCHBEIN Model 400 NS continues to lead sewing innovation for the Seed Bagging Industry

04/28/2017

Innovating Open Mouth Feed Bagging with the 1800 RBH Robotic Bag Placer

04/13/2017

Feed Bagging Case Study: Kreamer Feed

03/18/2017